Rubber Molding

Rubber molding is a manufacturing process that shapes rubber into specific forms using molds. This versatile technique is employed to create custom parts for various industries, ensuring precise dimensions, durability, and performance. Ideal for producing seals, gaskets, and other components, rubber molding offers flexibility in design and material selection for a wide range of applications.

Rubber Molding Common Part Types

-

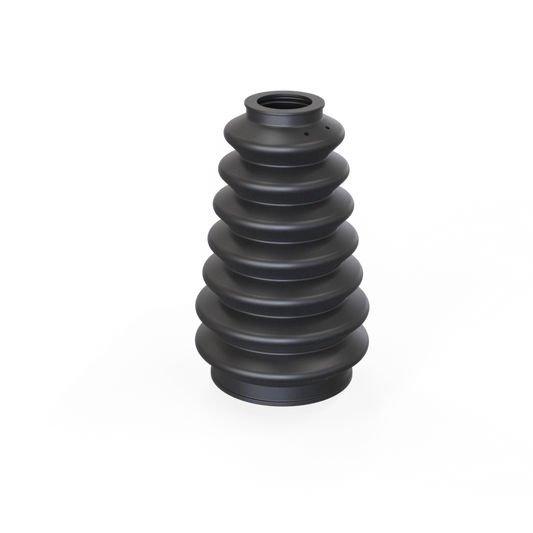

Boots/Bellows

Regular price $0.00Regular priceUnit price / per -

Bump Stops

Regular price $0.00Regular priceUnit price / per -

Premium Window Trim Seals - Silicone & EPDM Rubber Gaskets

Regular price $0.00Regular priceUnit price / per -

Molded Crumb Rubber Parts

Regular price $0.00Regular priceUnit price / per -

NBR/Nitrile Bumper for Light Switches

Regular price $0.00Regular priceUnit price / per -

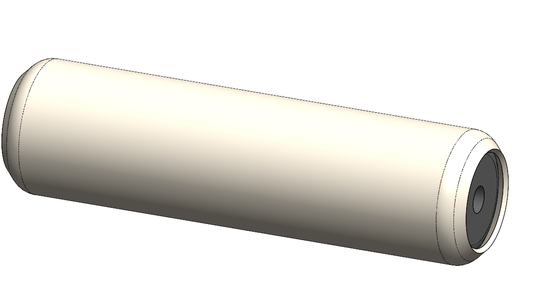

Neoprene Sleeves/Grommets/Couplers

Regular price $0.00Regular priceUnit price / per -

Cab Chassis Mounts/Isolators

Regular price $0.00Regular priceUnit price / per -

Engine Mounts

Regular price $0.00Regular priceUnit price / per -

Electrical Connector Grommet

Regular price $0.00Regular priceUnit price / per -

Spark Plug Boot

Regular price $0.00Regular priceUnit price / per -

Heater Element Connection Seal

Regular price $0.00Regular priceUnit price / per -

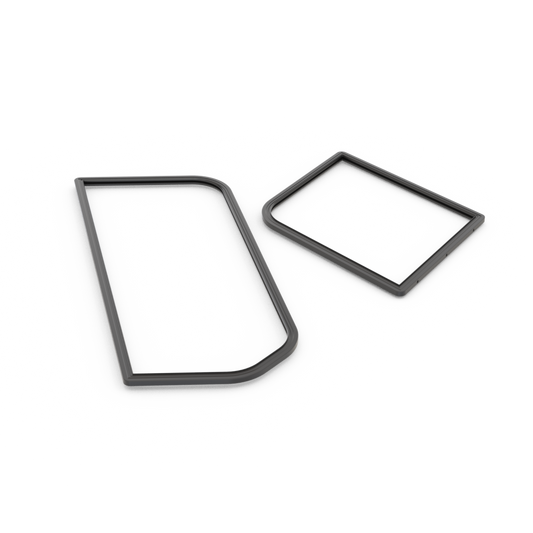

Silicone Perimeter Seals for Electrical Connectors

Regular price $0.00Regular priceUnit price / per -

Silicone Wire Seals

Regular price $0.00Regular priceUnit price / per

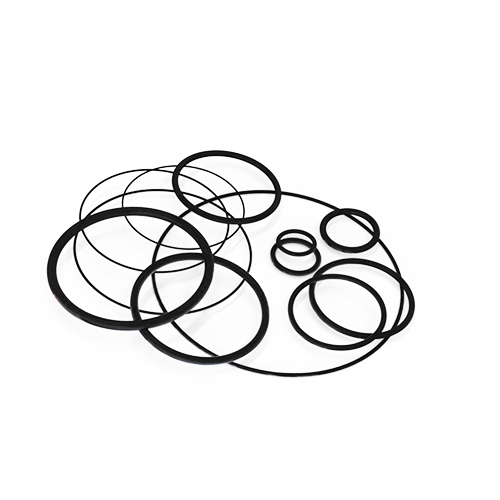

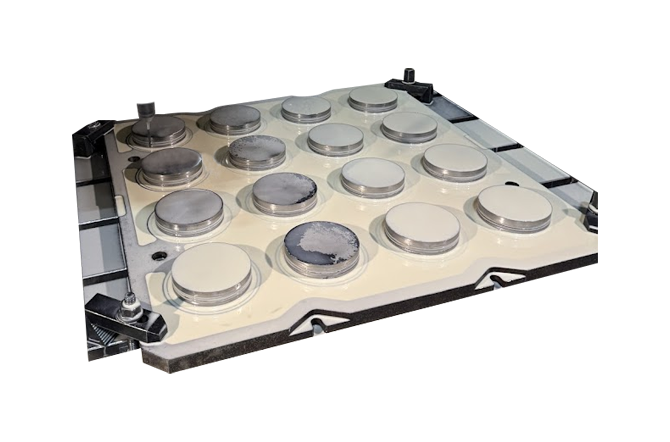

Compression Molding

Compression Molding Is An Ideal Manufacturing Process For Producing a wide variety of rubber parts from small o rings to large rubber floor mats. This Method Involves Placing A Pre-measured Amount Of Material, Typically In The Form Of A Rubber Compound Into A Heated Mold Cavity. The Mold Is Then Closed, And Pressure Is Applied To Shape The Material Into The Desired Form. The Heat Causes The Material To Cure Or Harden, Solidifying The Part Into Its Final Shape.

Transfer Molding

Transfer molding is a versatile manufacturing process that combines elements of both injection molding and compression molding to produce high-quality, detailed, and high-strength components. This method is particularly valued for its ability to create parts with excellent surface finishes and precise geometries, making it well-suited for industries where precision and durability are critical, such as in the production of electrical components, seals, and specialized industrial parts.

Injection Molding

With 24/7 production with presses up to 500T we can handle all of your injection molding product needs. Thermoplastic and thermoset machines. TPV (Santoprene), TPU, PVC (flexible), EPDM, silicone FKM and much more!

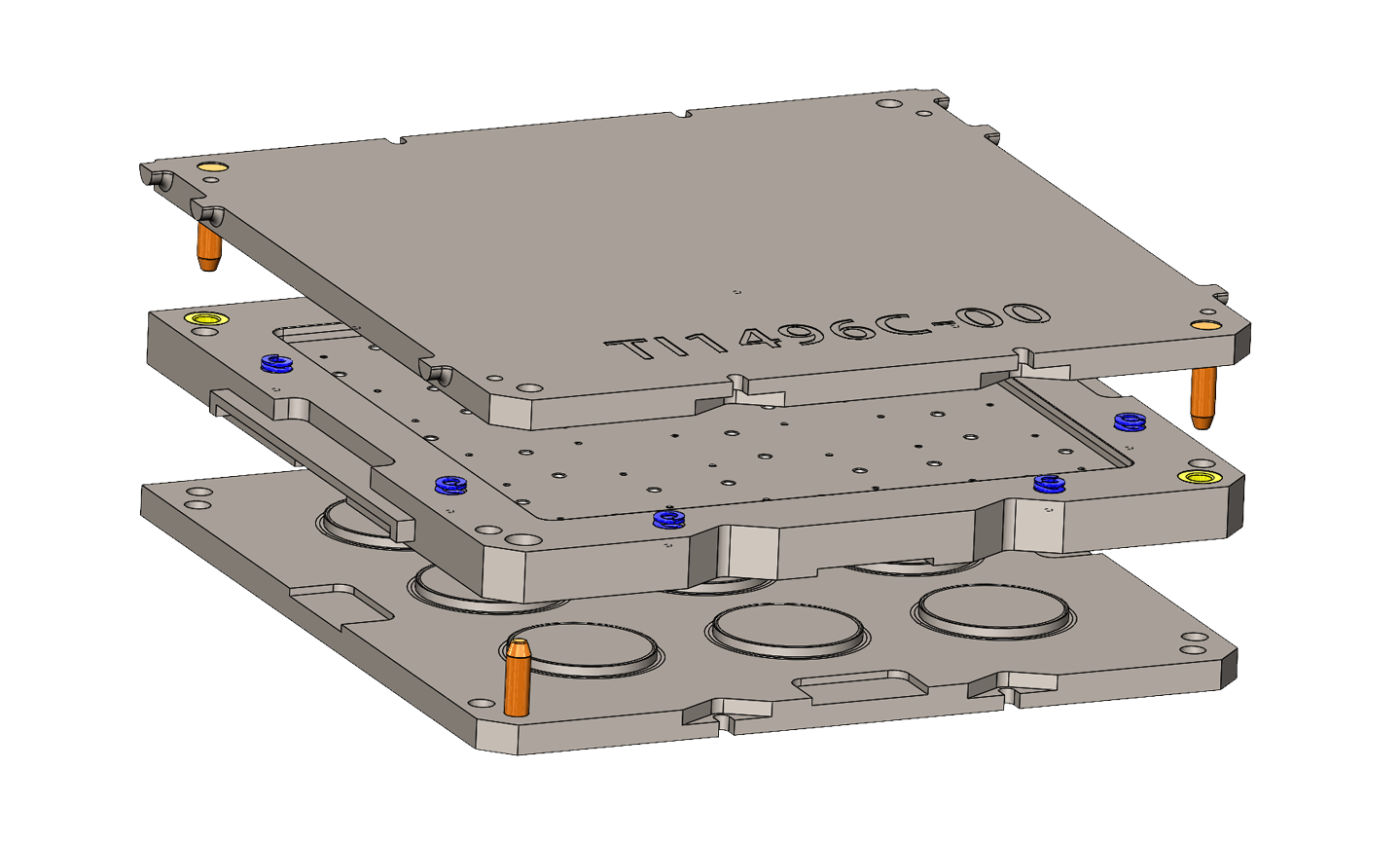

Mold Making

With 45 CNC machines running 24/7 and more than 50 engineers, we machine a wide variety of molds in house. Metal raw materials are stocked, allowing us to sprint into production in industry leading time.

Quality

For Parts Up To 80mm In Diameter And 30mm Tall We Can Do A 100% Inspection With The Top Of The Line Visual Inspection System That Can Inspect Up To 14 Parts A Second. Our Equipment Can Measure The Cross Section, Visually Inspect Surfaces Using Ai, Detect/measure Flash, Measure Flatness, And Check For The Presences Of Bubbles/cuts Or Fractures Ensuring Every Part Is Defect Free. For Larger Parts We Also Have 3d Scanners, Probes And A Keyence Im8030t Visual Inspection System For Doing Spot Or Sample Measurements.

Materials

Rubber Mexico Has 3 Chemists, A Full Service Rubber Lab That Supports Our Molding Department, But That Also Allows Us To Compound Nearly All Of The Rubber That We Use Internally. We Have Large Silicone Kneaders Allowing Us To Compound Silicone From The Polymer, Unlike Nearly Every Other Silicone Parts Manufacturer That Purchases Just Adds Colorant And Curatives On A Two Roll Mill. We Are One Of The Largest Manufacturers Of Silicone And Fluorosilicone Products In North America With Hundreds Of Existing Compounds That We Have Developed Over Decades. Very Few Companies Have More Experience Or Scale With Silicone Rubber Than Us, We Cannot Be Beat With Silicone Molded Products.

Need a quote?

Don't hesitate and reach us! Our customer service team would be happy to assist you.