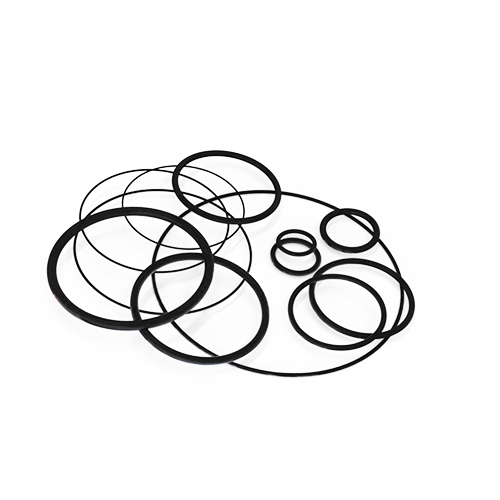

Fluoroelastomer (FKM/Viton)

Fluoroelastomer (FKM/Viton)

FKM (Fluoroelastomer/Viton): Premium High-Performance Elastomer

Fluoroelastomer (FKM), commonly known by the trade name Viton®, is a premium synthetic rubber engineered for extreme chemical resistance, high-temperature performance, and long-term durability in the most demanding industrial environments. Specified across aerospace, automotive, chemical processing, and oil & gas applications, FKM delivers unmatched sealing reliability where standard elastomers cannot survive.

Key Properties of FKM Rubber

- Exceptional Chemical Resistance: Superior resistance to acids, fuels, oils, solvents, and aggressive chemicals

- High Temperature Performance: Continuous operation from -20°F to 400°F (-29°C to 204°C), with specialty grades to 500°F

- Fuel & Oil Resistance: Outstanding resistance to petroleum fuels, synthetic oils, and aromatic hydrocarbons

- Low Permeability: Minimal gas and fluid permeation—ideal for critical sealing applications

- Oxidation & Aging Resistance: Excellent long-term stability in high-temperature oxidative environments

- Compression Set Resistance: Superior resistance to permanent deformation at elevated temperatures

- Flame Resistance: Self-extinguishing with excellent flame and smoke resistance

Common Applications & Uses

- Aerospace: Fuel system seals, O-rings, gaskets for jet fuel and hydraulic systems

- Automotive: Engine seals, fuel injector O-rings, transmission seals, turbocharger gaskets

- Chemical Processing: Pump seals, valve seats, gaskets for aggressive chemical environments

- Oil & Gas: Downhole seals, wellhead equipment, high-temperature/high-pressure applications

- Semiconductor: Plasma-resistant seals, vacuum chamber gaskets, chemical delivery systems

- Industrial: High-temperature hoses, expansion joints, chemical-resistant coatings

- Pharmaceutical: Sterile seals, autoclave gaskets, chemical-resistant components

Advantages of FKM

- Industry-leading chemical resistance—compatible with acids, fuels, oils, and aggressive solvents

- Highest continuous temperature rating among common elastomers (up to 400°F standard, 500°F specialty)

- Exceptional resistance to aromatic and chlorinated hydrocarbons (benzene, toluene, TCE)

- Superior compression set resistance at elevated temperatures

- Extremely low permeability to gases and fluids for critical sealing

- Excellent oxidation and weathering resistance for long service life

- Flame-resistant and self-extinguishing properties

- Multiple grades available for specific chemical and temperature requirements

Limitations & Disadvantages

- High Cost: Significantly more expensive than NBR, neoprene, EPDM, and other standard elastomers

- Poor Low-Temperature Flexibility: Limited flexibility below -20°F; specialty low-temp grades required for cold environments

- Steam & Hot Water Incompatibility: Not suitable for steam or hot water applications—EPDM is superior

- Polar Solvent Sensitivity: Poor resistance to ketones, esters, and some amines

- Processing Complexity: Requires specialized compounding and curing processes

- Adhesion Challenges: Difficult to bond without specialized primers or surface treatments

FKM vs. Other Rubber Materials

FKM vs. NBR (Nitrile): FKM offers superior chemical resistance, higher temperature capability (400°F vs. 250°F), and better aromatic hydrocarbon resistance. NBR is more cost-effective with better low-temperature flexibility for standard petroleum applications. Use FKM for extreme conditions; NBR for cost-sensitive oil/fuel contact.

FKM vs. EPDM: FKM excels in fuel, oil, and chemical resistance with high-temperature performance, while EPDM is superior for weather, steam, and hot water applications. FKM is the choice for chemical/fuel systems; EPDM for outdoor sealing and water contact.

FKM vs. Silicone: Both offer high-temperature performance, but FKM provides superior fuel and oil resistance while silicone offers better low-temperature flexibility (-65°F) and broader temperature range. FKM is preferred for fuel/chemical contact; silicone for extreme temperature cycling without chemical exposure.

FKM vs. Neoprene: FKM significantly outperforms neoprene in chemical resistance, temperature capability, and compression set resistance. Neoprene is more economical for moderate-exposure applications. FKM is specified for severe chemical and high-temperature environments.

FKM vs. FFKM (Perfluoroelastomer): FFKM offers even broader chemical resistance and higher temperature capability (up to 600°F), but at significantly higher cost. FKM is the cost-effective choice for most demanding applications; FFKM for the most extreme chemical and thermal conditions.

FKM Grades & Types

- Type A (Dipolymer): Standard grade with excellent fuel and oil resistance—most common general-purpose FKM

- Type B (Terpolymer): Enhanced chemical resistance, particularly to acids and steam—broader compatibility

- Type F (Tetrapolymer): Superior low-temperature flexibility with maintained chemical resistance

- GLT/GFLT: Specialty low-temperature grades for cold-environment applications

- Extreme grades: High-temperature formulations for continuous service to 500°F

Technical Specifications

- Hardness Range: 55–90 Shore A (customizable by formulation)

- Specific Gravity: 1.80–1.95

- Tensile Strength: 1,000–2,500 psi (varies by grade)

- Elongation at Break: 150–300% (varies by formulation)

- Compression Set: Excellent at elevated temperatures (typically <25% at 200°C/392°F for 70 hours)

- Temperature Range: -20°F to 400°F continuous (-29°C to 204°C), specialty grades to 500°F

Why Choose FKM from Rubber Mexico?

Our FKM compounds are formulated for maximum chemical resistance, thermal stability, and sealing performance across aerospace, automotive, chemical processing, and oil & gas applications. With in-house molding, precision machining, and custom compounding capabilities, we deliver mission-critical FKM components engineered to your exact specifications and operating conditions.

Need a custom FKM solution? Contact us for material selection guidance, grade optimization, compound development, prototyping, and production support for your most demanding sealing challenges.

Learn about our other materials

Rubber Mexico has 100s of compounds for a variety of compounds made internally. Learn more about the other types of materials that we manufacturer and our material development capabilities.

Other Materials

-

Silicone Rubber

Regular price $0.00Regular priceUnit price / per -

Ethylene Propylene Diene Terpolymer (EPDM)

Regular price $0.00Regular priceUnit price / per -

Styrene Butadiene Rubber (SBR)

Regular price $0.00Regular priceUnit price / per -

Neoprene/Chloroprene Rubber (CR)

Regular price $0.00Regular priceUnit price / per -

Nitrile Butadiene Rubber (NBR)

Regular price $0.00Regular priceUnit price / per -

Fluoroelastomer (FKM/Viton)

Regular price $0.00Regular priceUnit price / per -

Thermoplastic Elastomers

Regular price $0.00Regular priceUnit price / per -

Fluorosilicone (FVMQ)

Regular price $0.00Regular priceUnit price / per -

Devulcanized Rubber Compounds

Regular price $0.00Regular priceUnit price / per -

Natural Rubber (NR)

Regular price $0.00Regular priceUnit price / per -

Acrylic Rubber (ACM)

Regular price $0.00Regular priceUnit price / per -

Ethylene Acrylic Rubber (AEM)

Regular price $0.00Regular priceUnit price / per -

Flexible PVC (Plasticized Polyvinyl Chloride)

Regular price $0.00Regular priceUnit price / per -

Polyurethane (PU/TPU)

Regular price $0.00Regular priceUnit price / per