Rubber Mexico

Custom Mold Making & Precision Tooling Services

Custom Mold Making & Precision Tooling Services

Industry-Leading Mold Making Capabilities

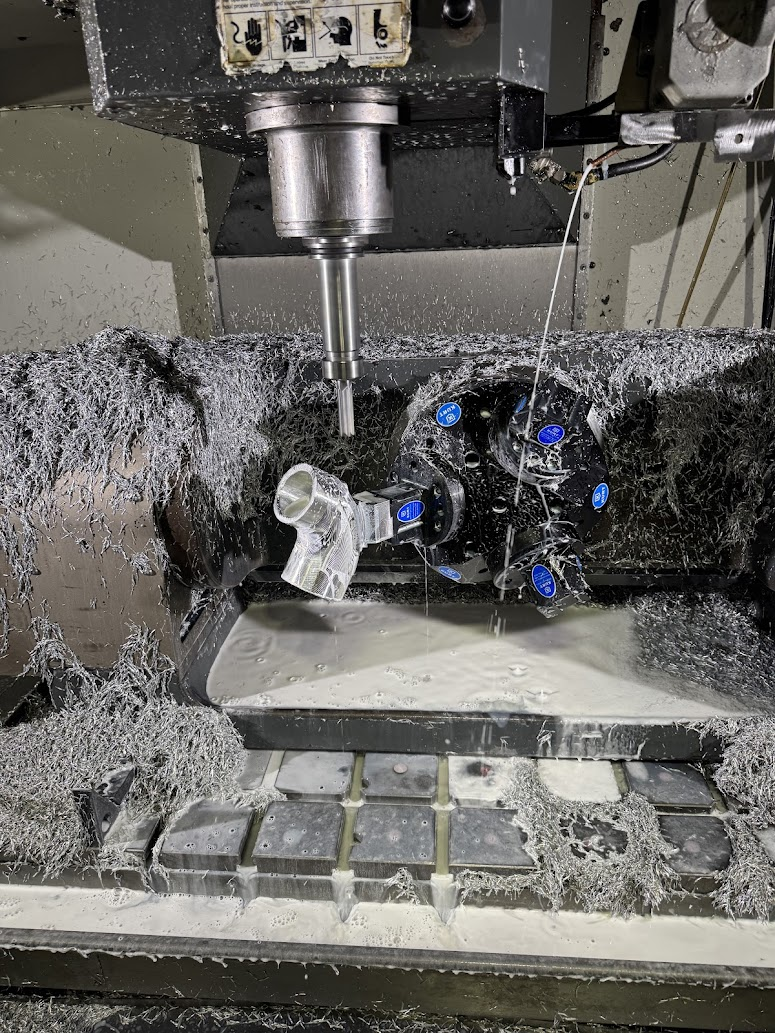

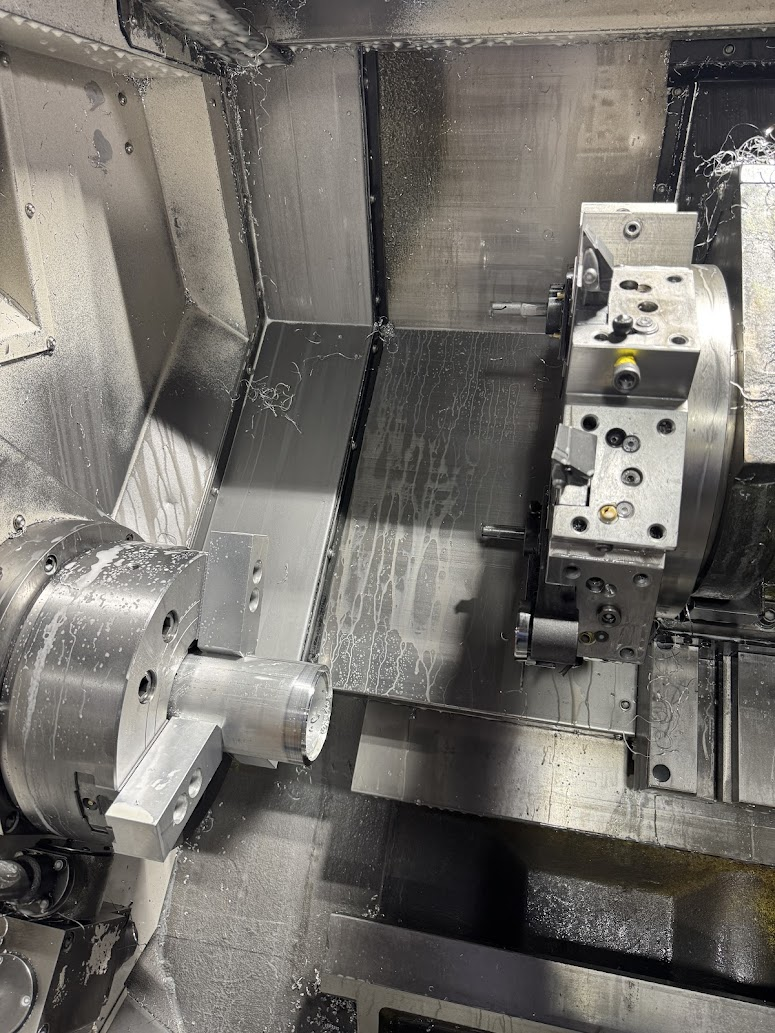

Experience unmatched precision and speed with our state-of-the-art mold making services. With more than 45 CNC machines running 24/7 and a team of over 50 skilled engineers, we deliver high-quality molds with industry-leading turnaround times.

Our Mold Making Advantages:

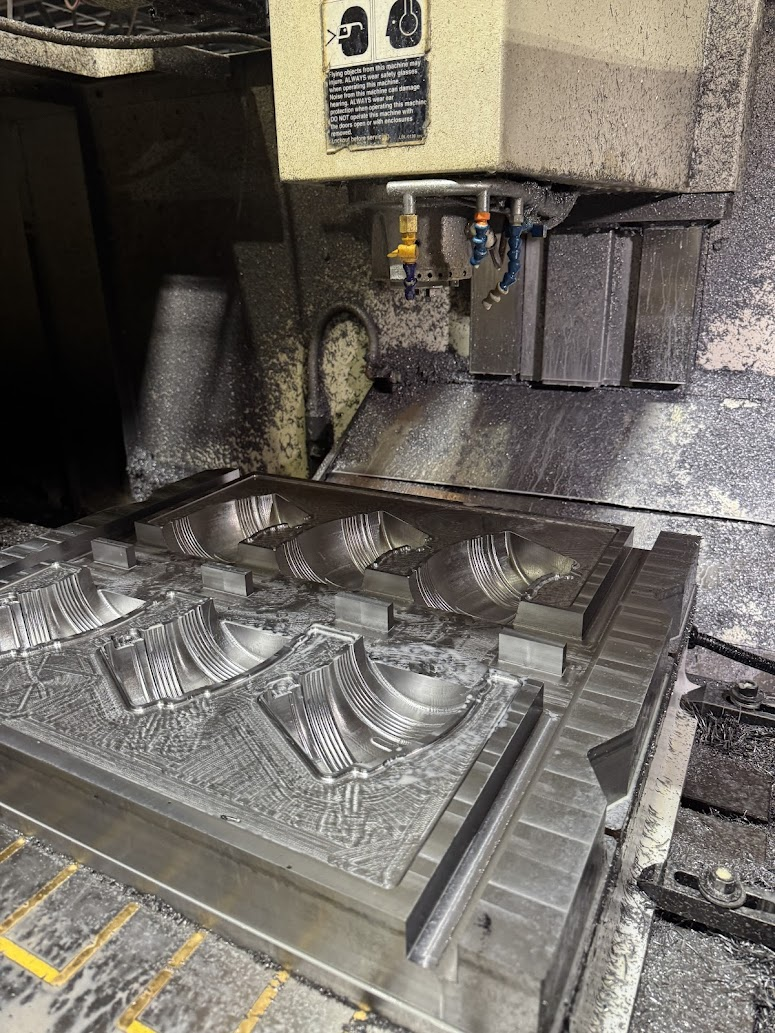

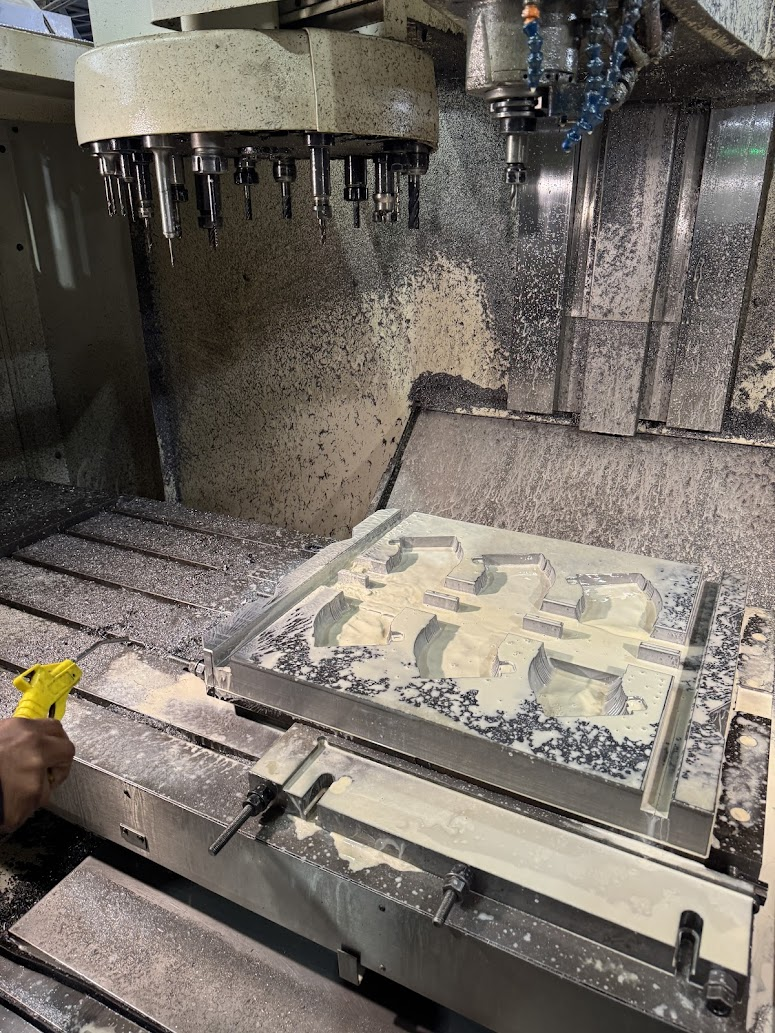

- Advanced CNC Machining - 45+ precision CNC machines operating continuously to ensure rapid production and consistent quality

- Expert Engineering Team - Over 50 experienced engineers dedicated to designing and manufacturing molds that meet exact specifications

- In-House Production - Complete control over the entire mold making process, from design to final production

- Rapid Turnaround - Stocked metal raw materials enable us to sprint into production with industry-leading delivery times

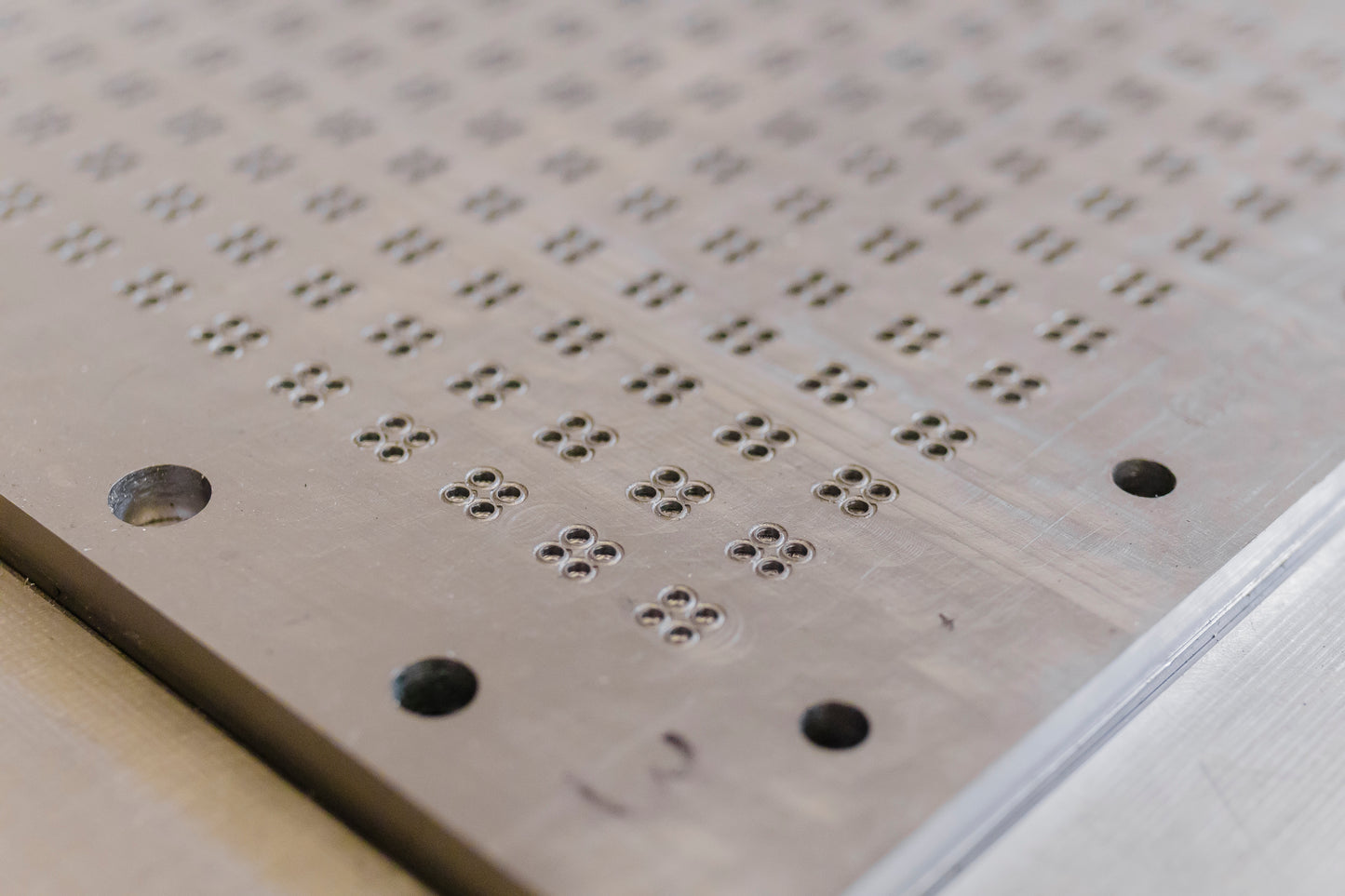

- Precision Tolerances - Advanced machining capabilities deliver tight tolerances for complex geometries and intricate designs

- Versatile Applications - Molds for compression molding, injection molding, transfer molding, and extrusion processes

Mold Types We Manufacture:

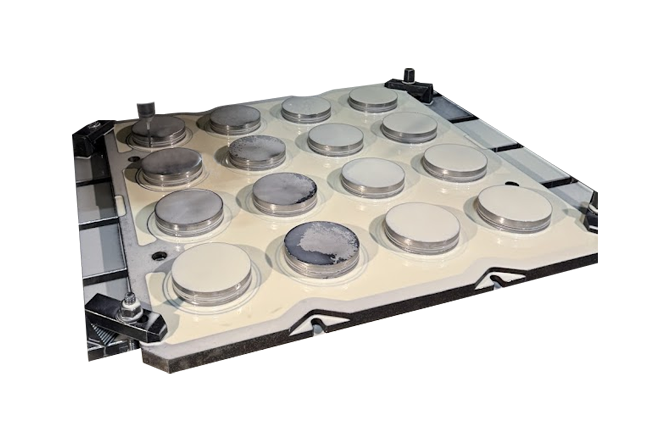

Compression Molds: Precision tooling for high-volume rubber component production with consistent quality

Injection Molds: Complex multi-cavity molds designed for efficient production of intricate rubber parts

Transfer Molds: Specialized tooling for components requiring precise material flow and minimal flash

Prototype Molds: Quick-turn tooling for product development and testing before full production

Polyurethane Molds: Aluminum molds or masters, we have made >1000 molds for cast polyurethane products from air filter bases to bushings we can do it all!

From initial design consultation through final production, our comprehensive mold making services ensure your rubber components are manufactured to the highest standards of quality and precision.

-

Dedicated Mold Assembly & Maintenance Team

Because of our scale we have established standardized dimensions and processes for our molds. We have 12 personnel dedicated to handling assembling new molds, preventive and corrective maintenance of our molds.

-

In-House Tool Crib & CNC Precision

We also have a full tool crib to go along our CNC department with 37 CNC machines. We have offline tool setters to ensure precision when making our molds. We stock a lot of endmills and typically have what we need in stock ready to go to immediately begin cutting a new mold. We stock lots of metal at our facility from sheet metal to up to 28" thick. We have the tool steel in stock ready to go for our new projects, we do not have to wait for an external supplier to cut to size and order steel for new projects. We are one of the largest rubber mold manufacturers in Mexico making hundreds of molds a year, so this scale allows us to provide very economical tooling at industry leading turnarounds.

Need a quote?

Don't hesitate and reach us! Our customer service team would be happy to assist you.