Ethylene Acrylic Rubber (AEM)

Ethylene Acrylic Rubber (AEM)

AEM (Ethylene Acrylic Rubber): Superior Heat & Oil Resistance Elastomer

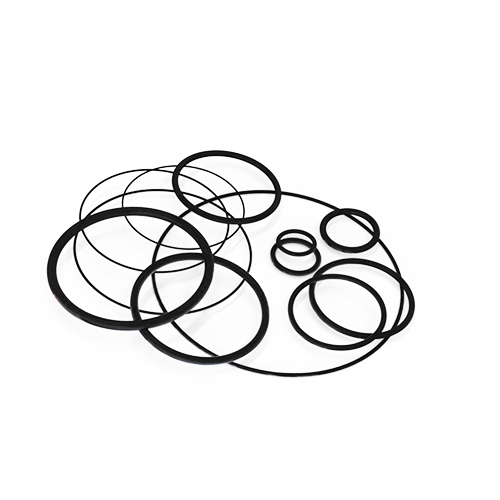

Ethylene Acrylic Rubber (AEM), commonly known by the trade name VAMAC®, is a premium synthetic elastomer engineered for exceptional resistance to hot oils, oxidation, and extreme temperatures. Designed specifically for automotive underhood and powertrain applications, AEM delivers reliable sealing performance in the harshest thermal and chemical environments where standard elastomers rapidly degrade.

Key Properties of AEM Rubber

- Exceptional Hot Oil Resistance: Superior resistance to hot engine oils, ATF, gear oils, and biodiesel at extreme temperatures

- Extreme Temperature Performance: Continuous operation from -40°F to 375°F (-40°C to 190°C)

- Outstanding Heat Aging: Excellent long-term stability in high-temperature oxidative environments

- Low Compression Set: Minimal permanent deformation at elevated temperatures—maintains sealing integrity

- Biodiesel Compatibility: Excellent resistance to biodiesel fuels (B20, B100) and biofuels

- Low-Temperature Flexibility: Maintains flexibility to -40°F—superior to ACM

- Ozone & Weather Resistance: Excellent outdoor durability and UV resistance

Common Applications & Uses

- Automotive Underhood: Turbocharger hoses, either as a liner for silicone rubber or hoses entirely from AEM typically with NOMEX reinforcement

- Powertrain: Crankshaft seals, camshaft seals, transmission seals, differential seals

- Engine Components: Oil pan gaskets, oil pump seals, PCV system components

- Fuel Systems: Biodiesel-compatible fuel hoses, seals, and O-rings

- Emission Control: EGR system seals, turbocharger gaskets, exhaust system components

- Heavy-Duty Vehicles: Truck and off-highway equipment seals for extreme-duty applications

- Industrial: High-temperature hydraulic seals, hot oil applications

Advantages of AEM

- Industry-leading hot oil resistance—outperforms NBR and ACM at temperatures above 300°F

- Exceptional heat aging and oxidation resistance for extended service life

- Superior low-temperature flexibility (-40°F) compared to ACM (-15°F)

- Excellent biodiesel and biofuel compatibility—critical for modern fuel systems

- Extremely low compression set at elevated temperatures maintains long-term sealing

- Outstanding ozone and weather resistance for underhood exposure

- Wide temperature range: -40°F to 375°F covers most automotive operating conditions

- Good resistance to coolants, glycols, and water-based fluids

- Cost-effective alternative to fluoroelastomers (FKM) for hot oil applications

Limitations & Disadvantages

- Limited Fuel Resistance: Not suitable for gasoline or aromatic fuels—FKM or fluorosilicone preferred

- Polar Solvent Sensitivity: Poor resistance to ketones, esters, and chlorinated solvents

- Higher Cost: More expensive than NBR and ACM, though less costly than FKM

- Processing Requirements: Requires specialized curing systems and post-cure for optimal properties

- Acid Resistance: Limited resistance to strong acids compared to FKM

- Availability: Less widely available than NBR or neoprene—specialty material

AEM vs. Other Rubber Materials

AEM vs. ACM (Acrylic): AEM offers superior low-temperature flexibility (-40°F vs. -15°F), higher maximum temperature (375°F vs. 350°F), and better biodiesel resistance. ACM is more cost-effective for moderate-temperature transmission applications. AEM is the choice for extreme underhood environments; ACM for transmission seals.

AEM vs. NBR (Nitrile): AEM significantly outperforms NBR in hot oil resistance and heat aging above 250°F, while NBR provides better fuel resistance and lower cost. Use AEM for extreme-temperature underhood seals; NBR for standard-temperature petroleum applications.

AEM vs. FKM (Viton): FKM offers broader chemical resistance and higher maximum temperature (400°F), but AEM is more cost-effective with better low-temperature flexibility for dedicated hot oil applications. AEM is the choice for biodiesel-compatible underhood seals; FKM for multi-chemical, extreme-temperature environments.

AEM vs. HNBR (Hydrogenated Nitrile): Both offer good hot oil resistance and low-temperature flexibility, but AEM provides superior heat aging and biodiesel compatibility. HNBR offers better fuel resistance. AEM is preferred for biodiesel and extreme heat; HNBR for broader fuel compatibility.

AEM vs. Silicone: Silicone offers wider temperature range (-65°F to 450°F) but poor oil resistance. AEM provides superior hot oil resistance with excellent high-temperature performance. AEM is the choice for hot oil sealing; silicone for extreme temperatures without oil contact.

AEM Grades & Formulations

- Standard AEM: General-purpose grade for underhood and powertrain seals—most common type

- High-temperature AEM: Enhanced formulations for continuous service to 375°F

- Low-temperature AEM: Optimized for improved cold flexibility while maintaining heat resistance

- Biodiesel-resistant AEM: Specially compounded for B20 and B100 biodiesel compatibility

Curing & Processing Considerations

AEM requires specialized curing systems (typically peroxide or soap cures) and benefits significantly from post-cure heat treatment to achieve optimal hot oil resistance, compression set properties, and heat aging performance. Proper post-cure is critical for long-term reliability in extreme-temperature applications.

Technical Specifications

- Hardness Range: 60–90 Shore A (customizable by formulation)

- Specific Gravity: 1.05–1.12

- Tensile Strength: 1,200–2,200 psi (varies by grade)

- Elongation at Break: 200–500% (varies by formulation)

- Compression Set: Excellent at elevated temperatures (typically <20% at 175°C/347°F for 70 hours)

- Temperature Range: -40°F to 375°F continuous (-40°C to 190°C)

- Volume Swell: Low swell in hot engine oils and biodiesel

Why Choose AEM from Rubber Mexico?

Our AEM compounds are formulated for maximum hot oil resistance, heat aging stability, biodiesel compatibility, and compression set performance across automotive underhood, powertrain, and heavy-duty applications. With in-house molding, precision machining, and custom compounding capabilities, we deliver mission-critical AEM seals and gaskets engineered to your exact specifications and extreme operating conditions.

Need a custom AEM solution? Contact us for material selection guidance, grade optimization, biodiesel compatibility testing, post-cure development, compound validation, prototyping, and production support for your most demanding underhood sealing challenges.

Learn about our other materials

Rubber Mexico has 100s of compounds for a variety of compounds made internally. Learn more about the other types of materials that we manufacturer and our material development capabilities.

Other Materials

-

Silicone Rubber

Regular price $0.00Regular priceUnit price / per -

Ethylene Propylene Diene Terpolymer (EPDM)

Regular price $0.00Regular priceUnit price / per -

Styrene Butadiene Rubber (SBR)

Regular price $0.00Regular priceUnit price / per -

Neoprene/Chloroprene Rubber (CR)

Regular price $0.00Regular priceUnit price / per -

Nitrile Butadiene Rubber (NBR)

Regular price $0.00Regular priceUnit price / per -

Fluoroelastomer (FKM/Viton)

Regular price $0.00Regular priceUnit price / per -

Thermoplastic Elastomers

Regular price $0.00Regular priceUnit price / per -

Fluorosilicone (FVMQ)

Regular price $0.00Regular priceUnit price / per -

Devulcanized Rubber Compounds

Regular price $0.00Regular priceUnit price / per -

Natural Rubber (NR)

Regular price $0.00Regular priceUnit price / per -

Acrylic Rubber (ACM)

Regular price $0.00Regular priceUnit price / per -

Ethylene Acrylic Rubber (AEM)

Regular price $0.00Regular priceUnit price / per -

Flexible PVC (Plasticized Polyvinyl Chloride)

Regular price $0.00Regular priceUnit price / per -

Polyurethane (PU/TPU)

Regular price $0.00Regular priceUnit price / per