Ultraviolet (UV) Resistance of Rubber Compounds (SAE J2527, ASTM D1148, ASTM D4329)

Ultraviolet (UV) Resistance of Rubber Compounds (SAE J2527, ASTM D1148, ASTM D4329)

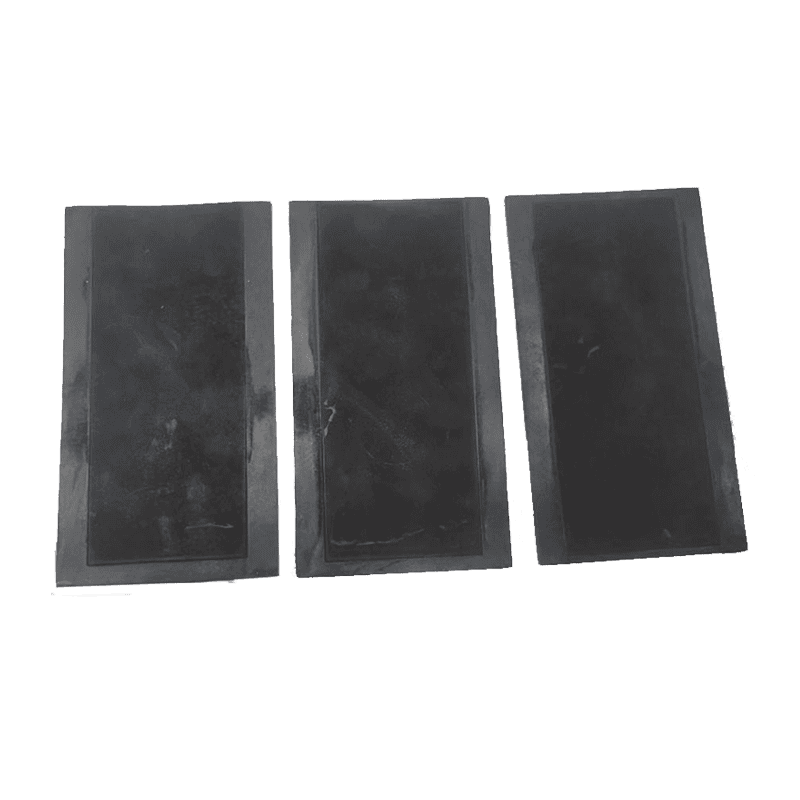

Rubber products are often exposed to sunlight and it is important to understand how the compounds used in rubber products will hold up to long term exposure of UV radiation from the sunlight exposure. Rubber materials can change in color, and degrade over time with long term exposure to sunlight. Certain colors like black are more resistant to aging, but the type of rubber polymer and the formulation of the compound contribute in large part to the UV resistance of the compound. Certain materials like silicone and EPDM have excellent UV aging resistance, while other rubbers like SBR are more prone to color changes and degradation.

The most common tests that we do to measure the UV resistance of our rubber compounds are: SAE J2527, ASTM D1148, ASTM D4329, ASTM G154, ASTM G155. In these tests cured rubber specimens are placed in a climate controlled chamber and exposed to UV radiation with a specific wavelength of light for a specified quantity of time. The color readings are taken before and after the UV exposure using a spectrophotometer which is a device that can take accurate unbiased color readings. The level of color change is given by the difference of these color readings and with this data the level of degradation is determined. The level of UV resistance can be specified and Rubber Mexico can perform this test periodically to ensure that our rubber compounds consistently meet the UV resistance needed by our customer's products.

Reach out to Rubber Mexico for all your rubber product needs that need excellent UV resistance so that the color and quality of the product overtime meets your expectations!

Need a quote?

Don't hesitate and reach us! Our customer service team would be happy to assist you.