Rubber Mexico

Silicone Wire Seals

Silicone Wire Seals

Silicone Wire Seals for Cable Entry Protection

Our precision-molded silicone wire seals provide reliable environmental protection at cable entry points in electrical connectors, junction boxes, and enclosures. Engineered for automotive, industrial, marine, and aerospace applications, these seals create watertight barriers around wire bundles and individual cables, preventing moisture, dust, and contaminants from entering assemblies while providing strain relief and cable retention.

Key Features & Benefits

- Watertight Cable Entry Sealing: Creates compression seal around cable jackets or individual wires to prevent moisture ingress

- Extreme Temperature Range: Silicone performs from -65°F to 400°F (-54°C to 204°C)—ideal for underhood and extreme-environment applications

- Strain Relief: Integrated strain relief features protect wire terminations from pull-out and flexing damage

- Cable Retention: Molded gripping features secure cables and prevent displacement during service

- Chemical Resistance: Excellent resistance to oils, fuels, coolants, and automotive fluids

- UV & Ozone Resistant: Superior outdoor durability without degradation or cracking

- Flexible Installation: Accommodates cable diameter variations and installation tolerances

Common Applications

- Automotive: Engine harness cable entries, sensor cable seals, lighting cable glands, underhood wire protection

- Electric Vehicles: Battery cable entries, charging cable seals, high-voltage cable glands

- Marine: Bulkhead cable penetrations, deck cable entries, bilge pump cable seals, navigation equipment

- Industrial: Control panel cable entries, motor junction boxes, outdoor equipment, instrumentation enclosures

- Aerospace: Avionics cable entries, environmental control system penetrations, flight control wiring

- Heavy Equipment: Construction machinery cable glands, agricultural equipment, mining vehicle harnesses

- Outdoor Electronics: Solar panel cable entries, wind turbine cable seals, outdoor lighting, security systems

How Wire Seals Protect Cable Entries

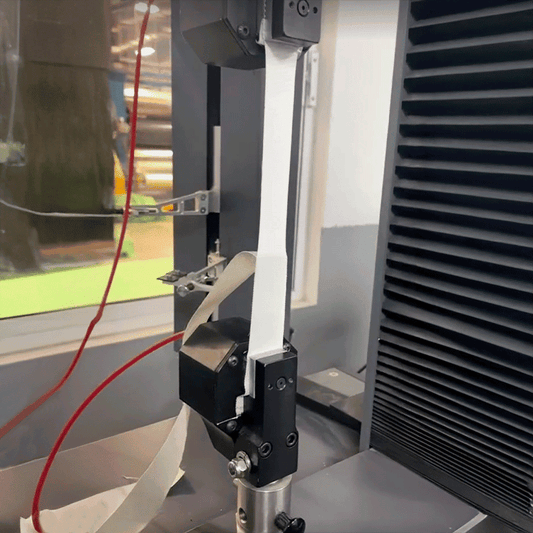

Wire seals install at cable entry points in connector housings, junction boxes, or enclosure walls. The seal's internal geometry compresses around the cable jacket or individual wires, creating a mechanical barrier that prevents water, dust, and contaminants from traveling along the cable into the protected assembly. Integrated strain relief features distribute cable loads to prevent damage to wire terminations, while retention features prevent cable pull-out during vibration and handling.

Wire Seal Configurations

- Single-Wire Seals: Individual seals for one wire or cable—maximum sealing performance per conductor

- Multi-Wire Seals: Multiple cavities for sealing 2–12+ wires in a single seal component

- Cable Gland Style: Threaded or snap-fit designs for panel-mount cable entry applications

- Push-Through Seals: Flexible membrane with pre-molded or field-cut wire passages

- Split Seals: Two-piece designs for retrofit installation on existing cable assemblies

- Overmolded Cable Seals: Seal molded directly onto cable for permanent environmental protection

Why Silicone for Wire Seals?

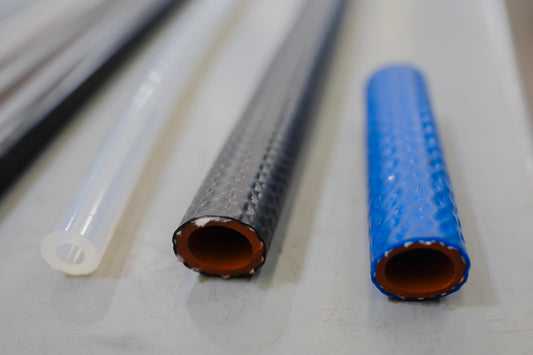

Silicone is the preferred material for wire seals due to its exceptional temperature range, compression set resistance, and environmental durability. Unlike EPDM or neoprene, silicone maintains sealing integrity and flexibility from arctic cold (-65°F) to underhood heat (400°F) without hardening or losing compression force. Silicone's superior UV and ozone resistance ensures decades of outdoor service without cracking, while its chemical resistance protects against automotive fluids, oils, and cleaning agents. The material's flexibility accommodates cable movement and thermal expansion while maintaining constant sealing pressure around conductors.

Design Considerations

- Cable Diameter Range: Seals designed to accommodate specific cable OD ranges with 10–20% compression

- Strain Relief Geometry: Molded ribs, tapers, or boots distribute cable loads and prevent kinking

- Retention Features: Internal gripping ribs, barbs, or compression zones prevent cable pull-out

- Material Hardness: Typically 20–60 Shore A for optimal sealing, flexibility, and installation ease

- Mounting Style: Snap-fit, threaded, press-fit, or adhesive-backed configurations

- Color Options: Available in black, gray, red, or custom colors for cable identification

Performance Standards & Testing

Our silicone wire seals are designed and tested to meet automotive and industrial cable sealing standards including IP67/IP68 ingress protection ratings, UL cable gland specifications, NEMA enclosure sealing requirements, and automotive OEM validation protocols. Testing includes water immersion, pressure testing, cable pull-out force, thermal cycling, vibration resistance, and long-term aging validation.

Material Properties

- Material: High-grade silicone rubber (VMQ/PVMQ)

- Hardness: 20–60 Shore A (customizable by application)

- Temperature Range: -65°F to 400°F continuous (-54°C to 204°C)

- Tensile Strength: 1,000–1,400 psi

- Elongation: 400–700%

- Tear Strength: 100–200 pli (Die B)

- Compression Set: Excellent (typically <25% at 350°F for 70 hours)

- Dielectric Strength: 500+ V/mil

IP Rating Capabilities

- IP67: Dust-tight and protected against temporary water immersion (1 meter for 30 minutes)

- IP68: Dust-tight and protected against continuous water immersion (depth and duration per specification)

- IP69K: Dust-tight and protected against high-pressure, high-temperature spray cleaning

Custom Molding & Engineering Support

We specialize in custom wire seal design and molding for OEM cable entry applications. Our engineering team collaborates with your cable specifications, entry point geometry, and environmental requirements to design seals with optimized compression characteristics, strain relief features, and retention mechanisms. We support FEA analysis, prototype validation, pull-out force testing, environmental testing, and high-volume production with full traceability and quality documentation.

Installation Guidelines

- Verify cable diameter is within seal's specified range

- Clean cable jacket surface—remove oils, dirt, or contaminants

- For split seals: open seal halves and position around cable

- For push-through seals: thread cable through seal opening—lubrication may assist installation

- Install seal into housing, panel, or enclosure entry point until fully seated

- Verify seal compression is uniform around cable with no gaps or voids

- For threaded cable glands: tighten to specified torque to achieve compression

- Perform seal integrity testing per application requirements (water spray, immersion, etc.)

Strain Relief & Cable Protection

Proper strain relief is critical for preventing wire termination failures. Our wire seals feature engineered strain relief geometries that distribute cable loads over a larger area, preventing stress concentration at wire terminations. Molded tapers, ribs, and boots guide cable flexing while maintaining sealing integrity, extending cable assembly service life in high-vibration environments.

Quality Assurance

Every production lot undergoes dimensional inspection, hardness testing, compression set validation, cable pull-out force testing, and visual inspection to ensure consistent sealing and retention performance. We maintain full material traceability, process control documentation, and compliance with automotive IATF 16949 and aerospace AS9100 quality standards.

Why Choose Rubber Mexico for Wire Seals?

With decades of experience in precision silicone molding for automotive and industrial cable sealing applications, we deliver wire seals engineered for reliable environmental protection and cable retention. Our in-house tooling design, molding, and validation testing capabilities ensure dimensional accuracy, material consistency, and performance validation. From prototype to high-volume production, we support your cable entry sealing requirements with technical expertise and manufacturing excellence.

Need custom wire seals? Contact us with your cable specifications, entry point geometry, IP rating requirements, and environmental conditions. Our engineering team will design, prototype, test, and validate silicone wire seals optimized for your cable entry application.

Share

Need a quote?

Don't hesitate and reach us! Our customer service team would be happy to assist you.

You may also be interested

-

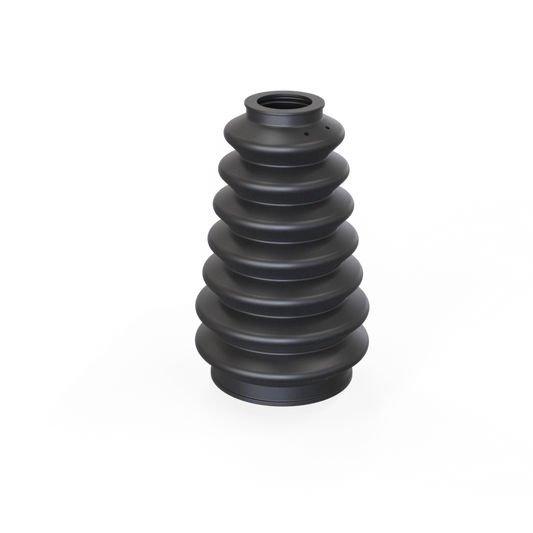

Boots/Bellows

Regular price $0.00Regular priceUnit price / per -

Bump Stops

Regular price $0.00Regular priceUnit price / per -

Charge air cooler hose with Stainless steel rings

Regular price $0.00Regular priceUnit price / per -

FKM lined silicone hoses

Regular price $0.00Regular priceUnit price / per -

FVMQ lined silicone hoses

Regular price $0.00Regular priceUnit price / per -

Premium Window Trim Seals - Silicone & EPDM Rubber Gaskets

Regular price $0.00Regular priceUnit price / per -

Molded Crumb Rubber Parts

Regular price $0.00Regular priceUnit price / per -

Fabric reinforced silicone drain tube/hose

Regular price $0.00Regular priceUnit price / per -

NBR/Nitrile Bumper for Light Switches

Regular price $0.00Regular priceUnit price / per -

Neoprene Sleeves/Grommets/Couplers

Regular price $0.00Regular priceUnit price / per -

Cab Chassis Mounts/Isolators

Regular price $0.00Regular priceUnit price / per -

Silicone + Fiberglass Tubing in UL Certified Couplings

Regular price $0.00Regular priceUnit price / per -

Engine Mounts

Regular price $0.00Regular priceUnit price / per -

Heater Hose (SAE J20)

Regular price $0.00Regular priceUnit price / per -

Coolant Hose

Regular price $0.00Regular priceUnit price / per -

Electrical Connector Grommet

Regular price $0.00Regular priceUnit price / per -

Spark Plug Boot

Regular price $0.00Regular priceUnit price / per -

EGR Silicone Hoses

Regular price $0.00Regular priceUnit price / per -

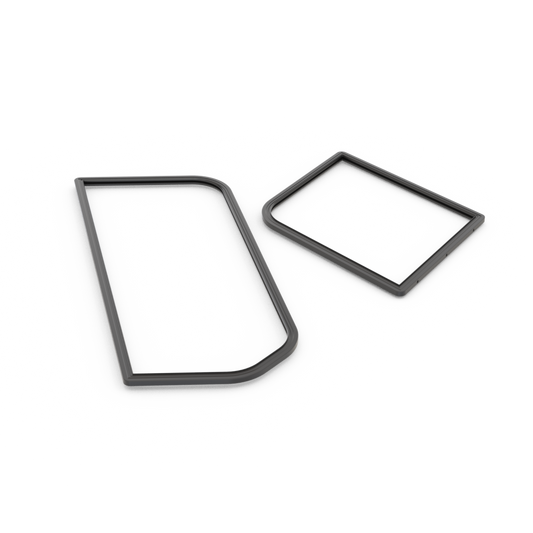

Silicone Perimeter Seals for Electrical Connectors

Regular price $0.00Regular priceUnit price / per -

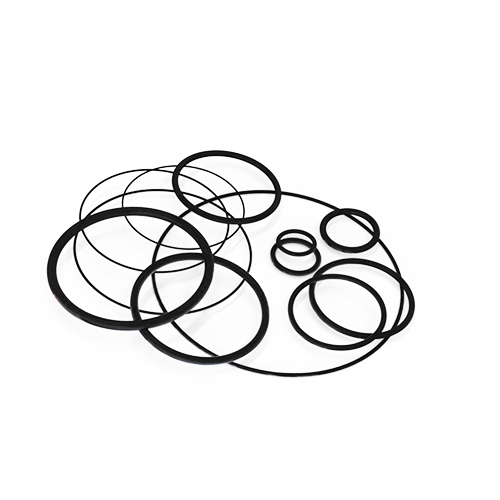

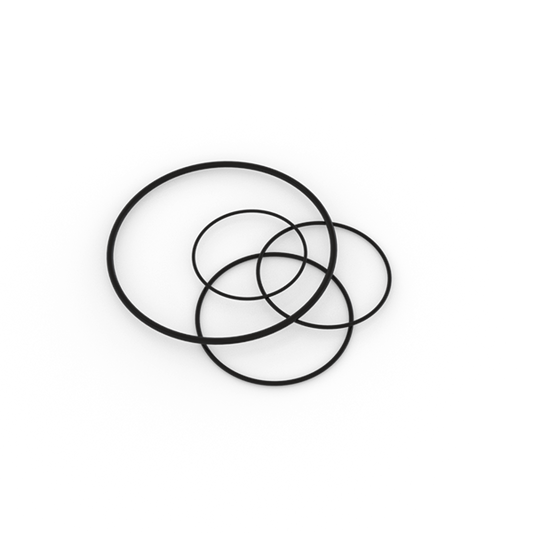

Silicone Wire Seals

Regular price $0.00Regular priceUnit price / per

More questions?

1000+ Products Produced

Learn more about our customer manufactured rubber products, we can do it all!