Ethylene Propylene Diene Terpolymer (EPDM)

Ethylene Propylene Diene Terpolymer (EPDM) is a versatile synthetic rubber engineered for superior weather resistance, thermal stability, and chemical compatibility. Widely specified across automotive, industrial, and commercial applications, EPDM delivers reliable performance in demanding outdoor and fluid-contact environments.

EPDM Rubber: High-Performance Synthetic Elastomer

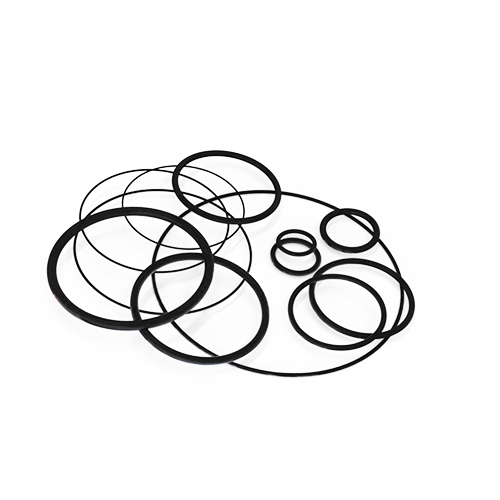

EPDM rubber is a durable synthetic elastomer designed for applications that require superior weather, UV, ozone, and water resistance. Its wide temperature range, excellent flexibility, and strong electrical insulation properties make EPDM ideal for seals, gaskets, hoses, and extruded profiles used in automotive, construction, HVAC, and industrial environments. At Rubber Mexico, we manufacture custom EPDM rubber components through precision extrusion and molding, delivering consistent quality and long-lasting performance for demanding applications.

Key Properties of EPDM Rubber

-

Color Stability

Resists fading and discoloration from sunlight exposure

-

Exceptional Weather Resistance

Outstanding resistance to UV, ozone, and oxidation—ideal for outdoor exposure

-

Wide Temperature Range

Performs reliably from -40°F to 300°F (-40°C to 150°C)

-

Chemical Compatibility

Excellent resistance to water, steam, alcohols, ketones, and dilute acids/alkalis

-

Electrical Insulation

Superior dielectric properties for electrical applications

-

Flexibility & Elasticity

Maintains flexibility at low temperatures with good compression set resistance

Common Applications of EPDM

Automotive Systems

Construction & Roofing

HVAC & Fluid Handling

Industrial Equipment

Key Advantages of EPDM Rubber

Superior outdoor durability

EPDM maintains its mechanical properties even under prolonged UV, ozone, and weather exposure, making it ideal for outdoor sealing, roofing, and automotive exterior components.

Cost-effective for weather sealing and water-contact applications

Because of its natural resistance to moisture and environmental aging, EPDM delivers long service life with lower material and maintenance costs in gaskets, seals, and hose systems.

Excellent steam and hot-water resistance

Unlike many elastomers, EPDM performs reliably in continuous hot-water and steam environments, making it suitable for HVAC systems, cooling circuits, and industrial fluid handling.

Low-temperature flexibility across a wide thermal range

EPDM stays flexible and crack-resistant at low temperatures, ensuring dependable sealing performance in cold-climate outdoor and automotive applications.

Good electrical insulation properties

Its inherent dielectric strength makes EPDM well-suited for cable jacketing, electrical boots, connectors, and high-voltage insulation components.

Available in multiple durometer ranges and formulations

EPDM can be customized in hardness, color, and compound chemistry to meet OEM specifications for compression set, tensile strength, and environmental resistance.

Why Choose EPDM from Rubber Mexico?

Our EPDM compounds are formulated for consistent quality and performance across automotive, industrial, and commercial applications. With in-house molding, extrusion, and bonding capabilities, we deliver precision-engineered EPDM components tailored to your specifications.

Need a custom EPDM solution?

Contact us for material selection guidance, prototyping, and production support.

Learn about our other materials

Rubber Mexico has 100s of compounds for a variety of compounds made internally. Learn more about the other types of materials that we manufacturer and our material development capabilities.

-

Silicone Rubber

Regular price $0.00Regular priceUnit price / per -

Ethylene Propylene Diene Terpolymer (EPDM)

Regular price $0.00Regular priceUnit price / per -

Styrene Butadiene Rubber (SBR)

Regular price $0.00Regular priceUnit price / per -

Neoprene/Chloroprene Rubber (CR)

Regular price $0.00Regular priceUnit price / per -

Nitrile Butadiene Rubber (NBR)

Regular price $0.00Regular priceUnit price / per -

Fluoroelastomer (FKM/Viton)

Regular price $0.00Regular priceUnit price / per -

Thermoplastic Elastomers

Regular price $0.00Regular priceUnit price / per -

Fluorosilicone (FVMQ)

Regular price $0.00Regular priceUnit price / per -

Devulcanized Rubber Compounds

Regular price $0.00Regular priceUnit price / per -

Natural Rubber (NR)

Regular price $0.00Regular priceUnit price / per -

Acrylic Rubber (ACM)

Regular price $0.00Regular priceUnit price / per -

Ethylene Acrylic Rubber (AEM)

Regular price $0.00Regular priceUnit price / per -

Flexible PVC (Plasticized Polyvinyl Chloride)

Regular price $0.00Regular priceUnit price / per -

Polyurethane (PU/TPU)

Regular price $0.00Regular priceUnit price / per