Mandrel Formed Hoses

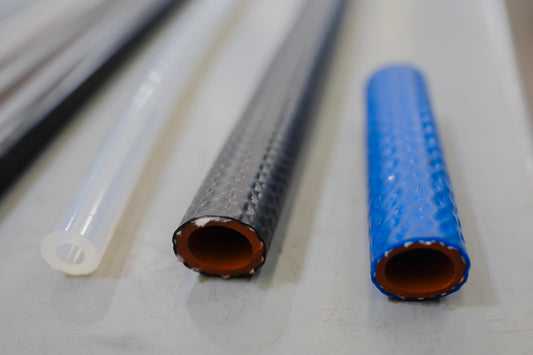

Formed fabric reinforced silicone hoses are made in a manufacturing process where silicone rubber is formed on a mandrel along with fabric reinforcing layers and often with a chemical resistant liner like FKM or fluorosilicone.

Custom Mandrel-Formed Hoses for OEM and Heavy-Duty Equipment

Designed for precise fit, smooth internal flow, and long-term durability. Manufactured with high-quality elastomers and reinforcements to meet automotive and industrial performance requirements.

Custom diameters, bends, materials, and reinforcements available.

High-Performance Mandrel-Formed Hoses for Demanding Applications

Explore our precision-engineered mandrel-formed hoses, crafted for exceptional durability and performance in demanding industries. Designed to handle the toughest applications, our hoses offer the perfect balance of strength, flexibility, and reliability. Whether you need high-performance capabilities or custom specifications, our advanced manufacturing techniques provide tailored solutions that ensure a perfect fit for your unique needs. Discover the ideal solution for your business by browsing our range of high-quality hoses.

Advanced Reinforcement Options

We offer a variety of reinforcement options for our silicone hoses, including Nomex/Aramid, polyester, and fiberglass. These reinforcements enhance the strength and durability of your hoses, making them ideal for high-performance applications in demanding environments like automotive, industrial, and aerospace

Want to add text or logos to your mandrel formed hoses?

Laser Marking vs Printing vs Stickers vs Embossing

There are multiple ways to add text, logos or markings to rubber products including laser marking, ink pad printing, inkjet printing, using embossings in the mold, and using stickers during the molding process.

Ver todos los detalles

Quality

For Parts Up To 80mm In Diameter And 30mm Tall We Can Do A 100% Inspection With The Top Of The Line Visual Inspection System That Can Inspect Up To 14 Parts A Second. Our Equipment Can Measure The Cross Section, Visually Inspect Surfaces Using Ai, Detect/measure Flash, Measure Flatness, And Check For The Presences Of Bubbles/cuts Or Fractures Ensuring Every Part Is Defect Free. For Larger Parts We Also Have 3d Scanners, Probes And A Keyence Im8030t Visual Inspection System For Doing Spot Or Sample Measurements.

Cleanliness of Rubber Product (ASTM 5774, SAE J1726)

A common requirement for hoses that we manufacturer is a level of cleanliness when tested to SAE J1726. In these tests we are able to quantify the level of particles in the inside of these hoses and ensure that they meet the level of cleanliness that our customers need and to minimize the amount of foreign objects that our products bring to the system.

Ver todos los detalles

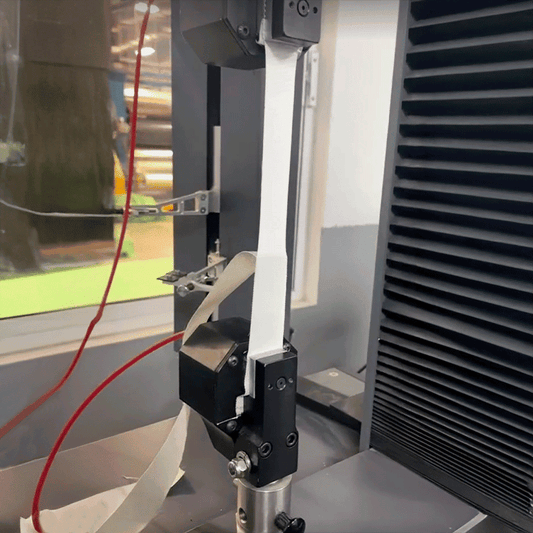

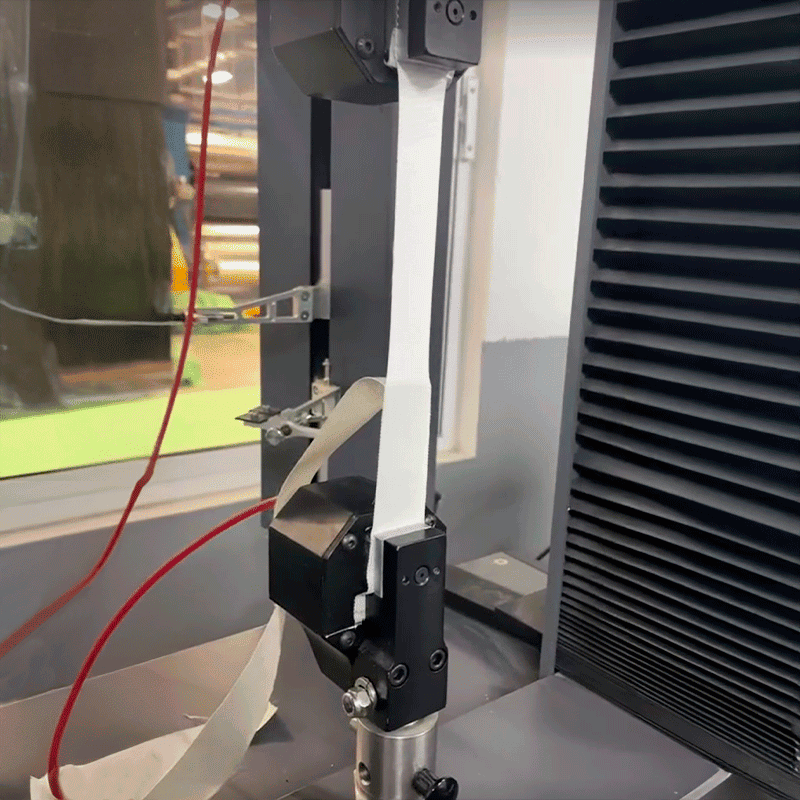

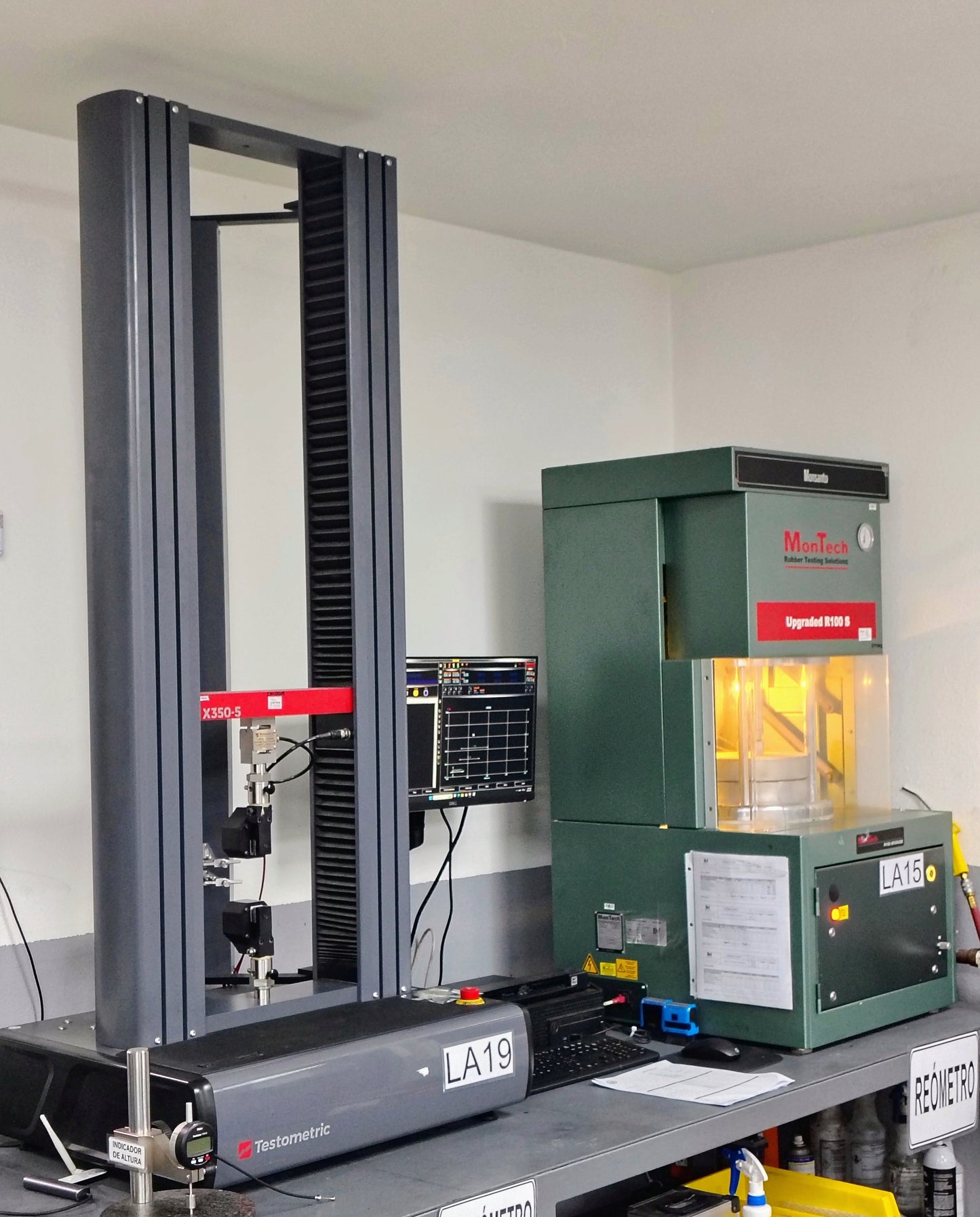

Adhesion (ASTM D429, ISO 36)

In hoses excellent adhesion of the rubber to fabric is critical for the performance of the hose. Delamination is a common failure in hoses. It is critical to measure the adhesion strength of rubber to the substates. In hoses it is common for fabrics to be added to provide additional strength including nomex (m-aramid), polyester and more. Most rubbers compounds do not have good adhesion to these fabrics without special additives in the compound. Rubber Mexico has lots of experience with developing compounds that adhere well to extruded fabric reinforced hoses, and formed/wrapped hoses.

Ver todos los detalles

Key Benefits of Mandrel Formed Hoses

Seamless internal construction for improved flow and reduced risk of leaks

Excellent resistance to kinking and collapse, even in tight bend radii

High dimensional accuracy for critical fluid and air transfer applications

Custom geometry capability, including straight sections, elbows, and multi-radius bends

Consistent wall thickness for reliable pressure and performance characteristics

Typical Applications for Mandrel Formed Hoses

Aerospace and transportation applications

Engineered for precision, reliability, and durability in critical systems where tight tolerances and consistent performance are essential.

Automotive cooling, air intake, and intercooler systems

Designed to withstand high temperatures, pressure fluctuations, and vibration while maintaining consistent airflow and reliable sealing in demanding automotive environments.

Chemical handling and process industries

Manufactured with compatible rubber compounds to resist aggressive chemicals, ensuring safe, long-lasting performance in processing and transfer systems.

Need a quote?

Don't hesitate and reach us! Our customer service team would be happy to assist you.

Product Types

-

Charge air cooler hose with Stainless steel rings

Precio habitual $0.00Precio habitualPrecio unitario / por -

FVMQ lined silicone hoses

Precio habitual $0.00Precio habitualPrecio unitario / por -

FKM lined silicone hoses

Precio habitual $0.00Precio habitualPrecio unitario / por -

Fabric reinforced silicone drain tube/hose

Precio habitual $0.00Precio habitualPrecio unitario / por -

Silicone + Fiberglass Tubing in UL Certified Couplings

Precio habitual $0.00Precio habitualPrecio unitario / por -

Heater Hose (SAE J20)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Coolant Hose

Precio habitual $0.00Precio habitualPrecio unitario / por -

EGR Silicone Hoses

Precio habitual $0.00Precio habitualPrecio unitario / por