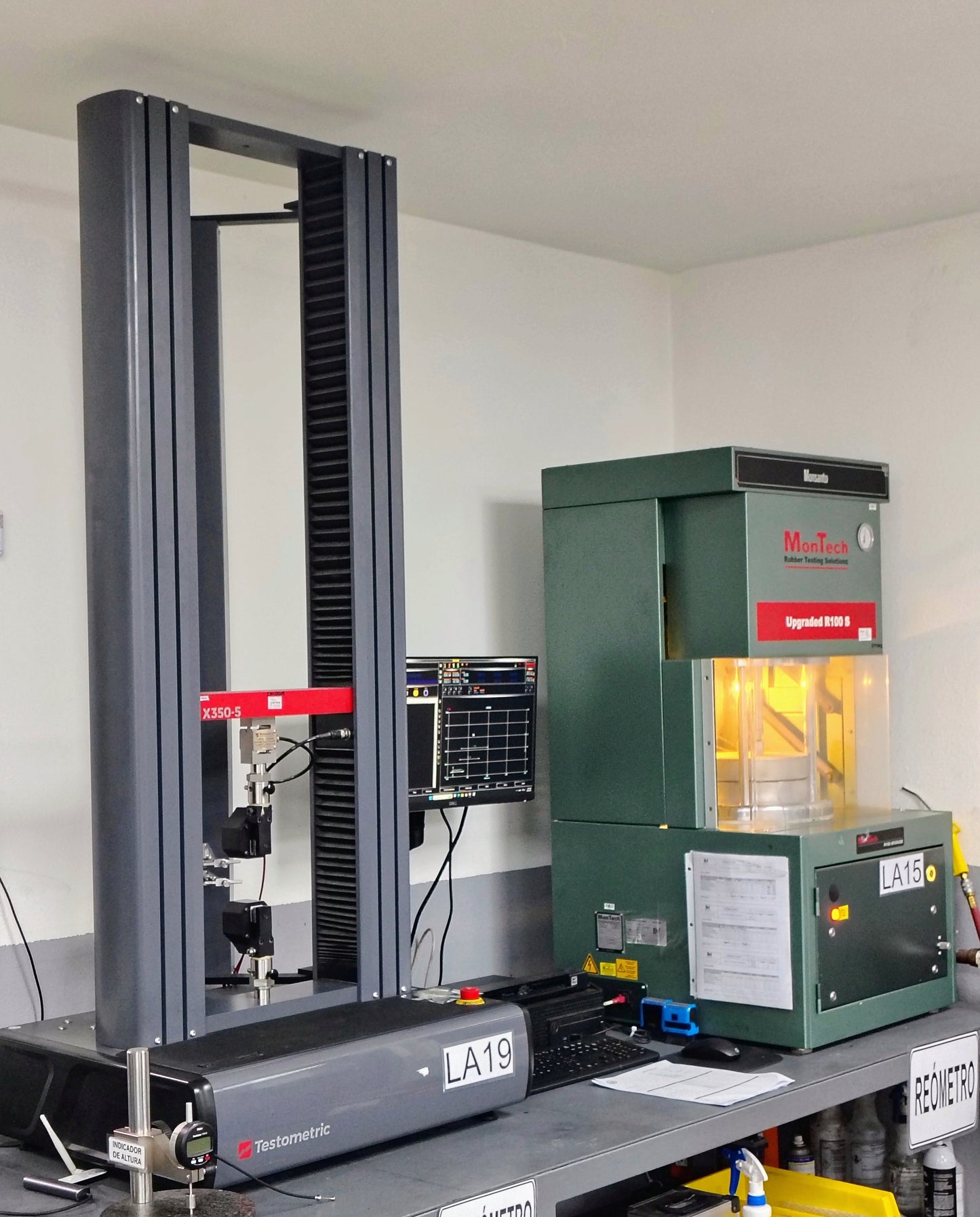

Adhesion (ASTM D429, ISO 36)

Adhesion (ASTM D429, ISO 36)

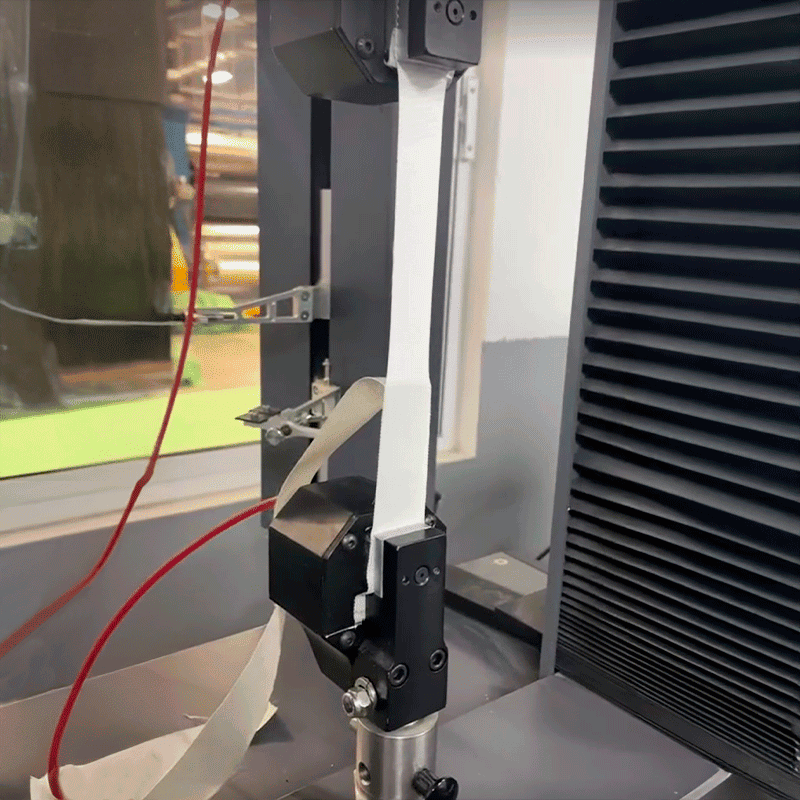

In some applications of rubber the adhesion of the rubber is critical for the application. Some applications where this property is important includes when rubber is bonded to fabrics in the case of hoses, or metals in the case of when rubber is overmolded to metal. Delamination is a common failure in both overmolded metal applications as well as in hoses. It is critical to measure the adhesion strength of rubber to the substates or materials that the rubber most adhere to in the application. In hoses it is common for fabrics to be added to provide additional strength including nomex (m-aramid), polyester and more. Most rubbers compounds do not have good adhesion to these fabrics without special additives in the compound. Rubber Mexico has lots of experience with developing compounds that adhere well to extruded fabric reinforced hoses, formed/wrapped hoses and other rubber products that have fabric reinforcement.

Rubber Mexico also has ample experience with overmolding rubber onto metal and plastics. Most rubber also do not want to adhere to these different substrates without special techiniques and additives so it is important to measure the adhesion strength and work with a rubber compounding company like Rubber Mexico that has the knowledge for these applications. For bonding to metals and plastics preparation of the substrates whether with ozone preparation, chemical etching, mechanical etching (with sanding, shot blasting, sand blasting etc) are great first steps to ensure the rubber has a well prepared surface to bond to. A rough and clean surface helps a lot with increasing the adhesion of rubber to some substrates. Rubber Mexico has automated equipment to prepare substrates for the mentioned preparations. For many applications it is also necessary to apply a primer to the substrate to increase the surface energy and compatability to bond with rubbers. There are also many steps that can be taken including certain additives that can be added to rubber compounds to improve the adhesion of the compound to different substrates. Common additives include a wide array of silanes which can act as a bridge between the rubber chemistry and the substrate chemistry.

Rubber Mexico is an expert when it comes to measuring and developing rubber products that need excellent adhesion to another material in the application. Come to Rubber Mexico for all your hose and rubber to metal needs!

Need a quote?

Don't hesitate and reach us! Our customer service team would be happy to assist you.