QUALITY ASSURANCE

At Rubber-Mexico, we are committed to delivering the highest quality products. To ensure precision, reliability, and consistency, we employ advanced testing and measurement techniques using state-of-the-art machinery. Our comprehensive quality control process include:

Quality assurance for rubber

Reómetro

We have advanced rheometers at our disposal, enabling us to thoroughly review the cure profile of our rubber compounds throughout both the compound development phase and as a final quality check during production. This ensures that each lot meets the exacting standards established for the compound’s performance. With this capability, we can quickly develop compounds internally and perform a comprehensive 100% lot check in production, guaranteeing that every material batch will perform as intended. Our Montech rheometer plays a crucial role in this process by enabling us to accurately measure and analyze the flow properties of materials. This device helps us evaluate critical parameters such as viscosity, curing characteristics, and other essential properties that directly impact product performance. Through precise measurement and analysis, we ensure optimal formulation and processing of polymers and other compounds, delivering reliable, high-performing products to our customers.

Ver todos los detalles

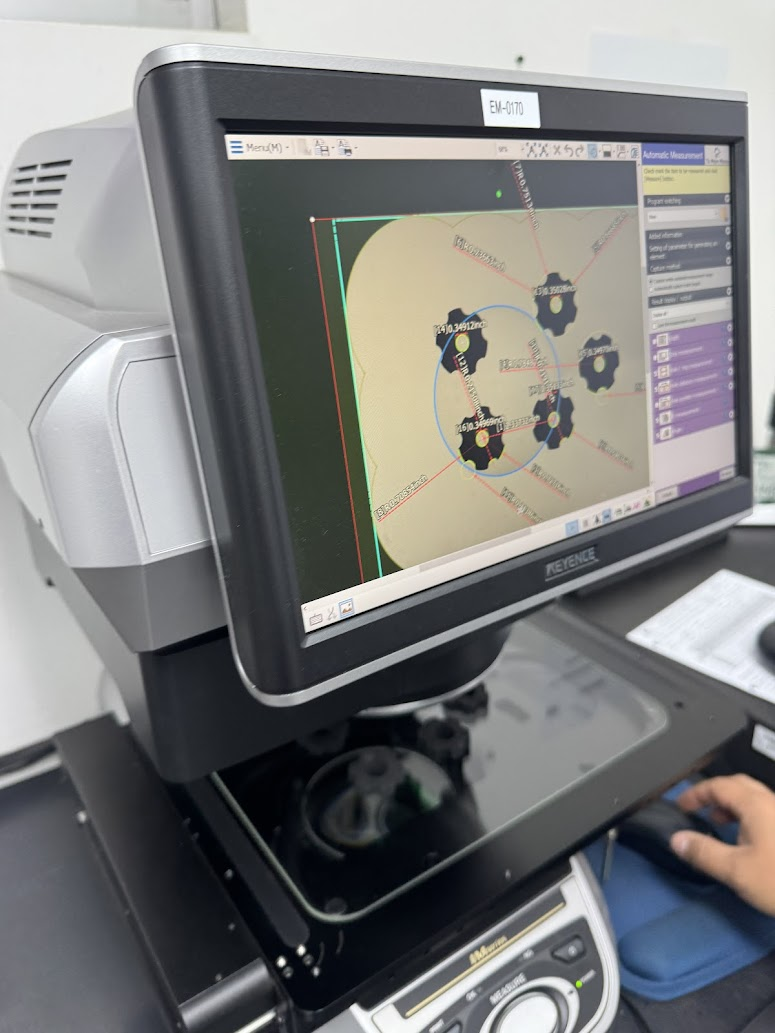

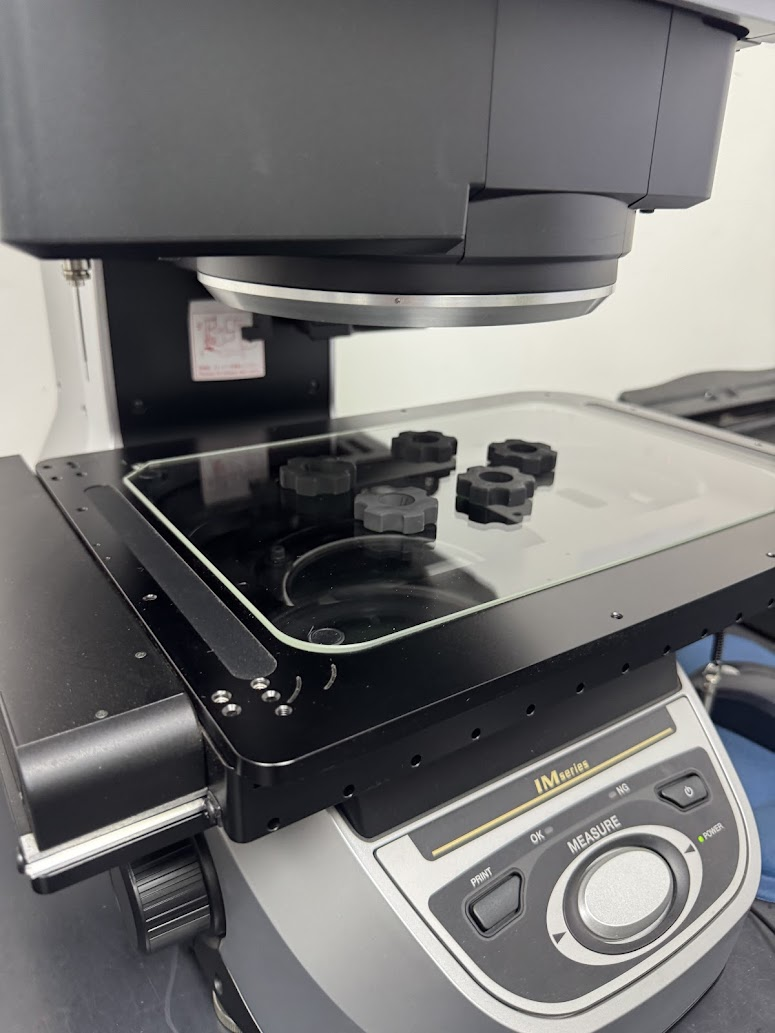

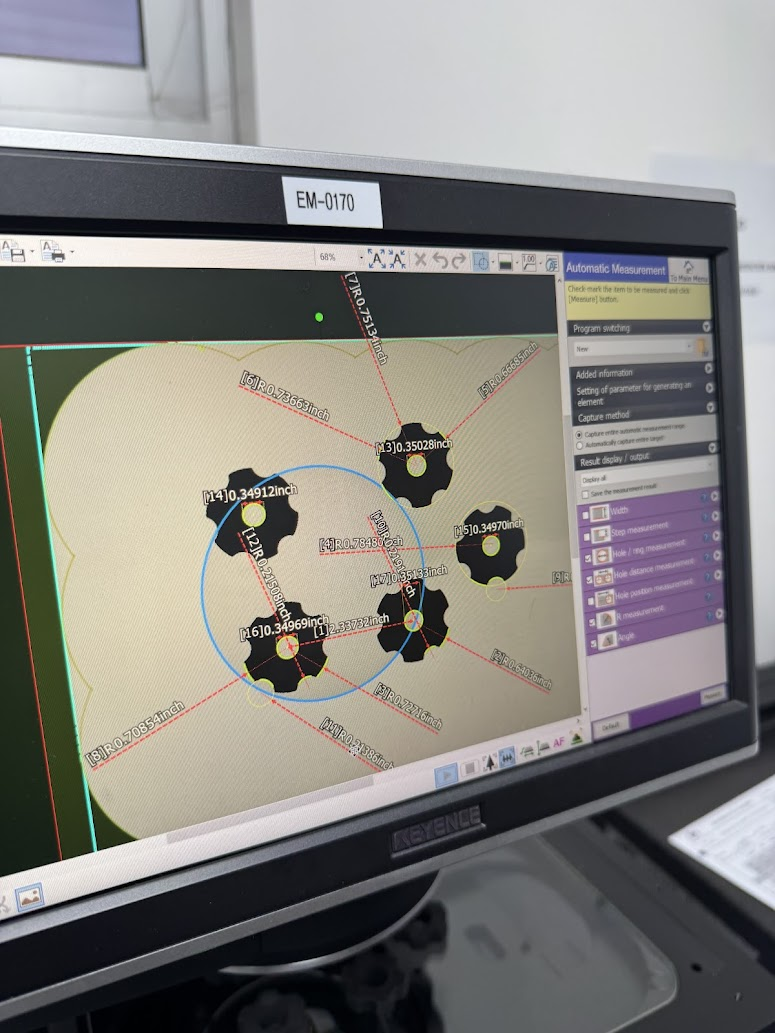

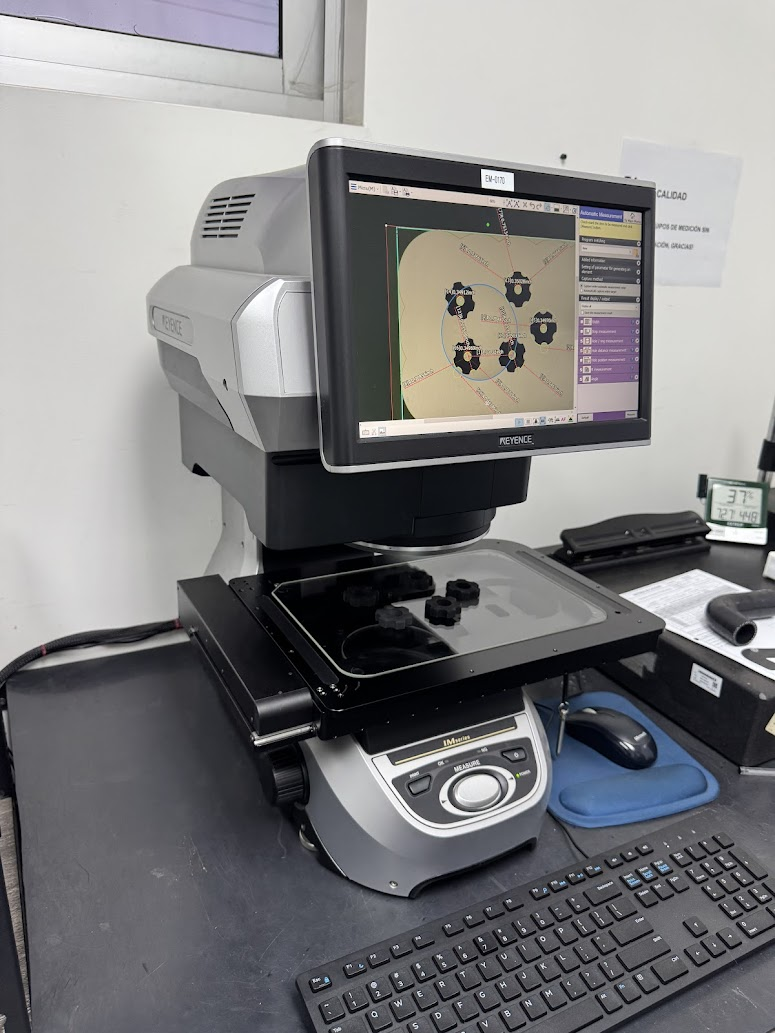

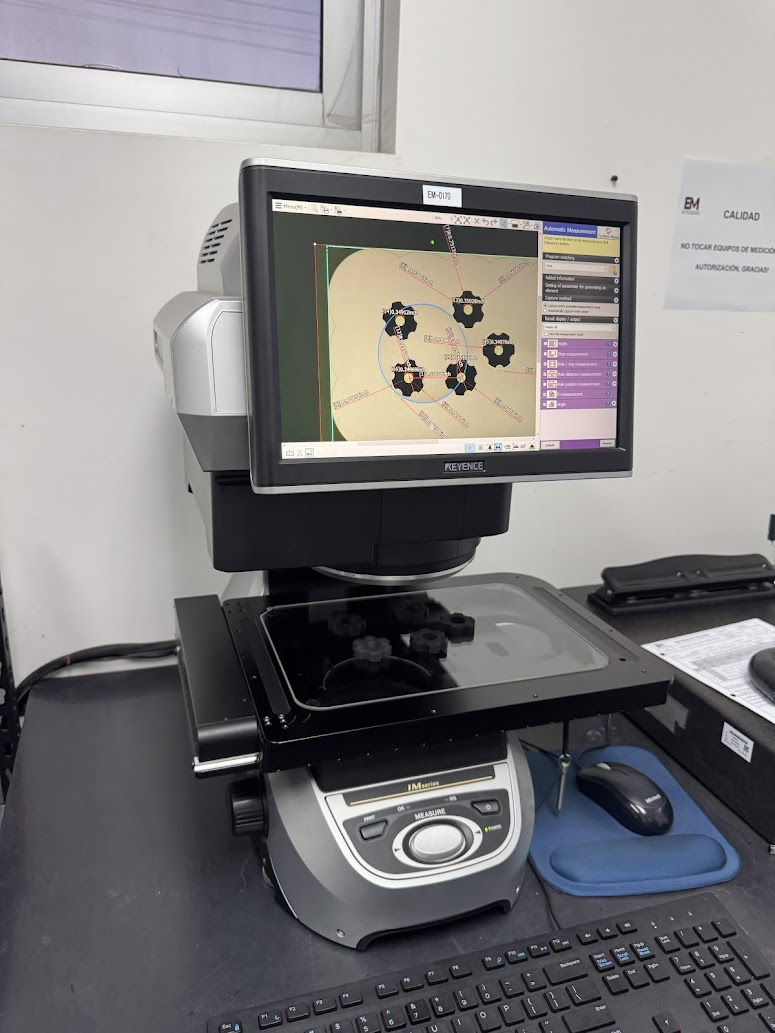

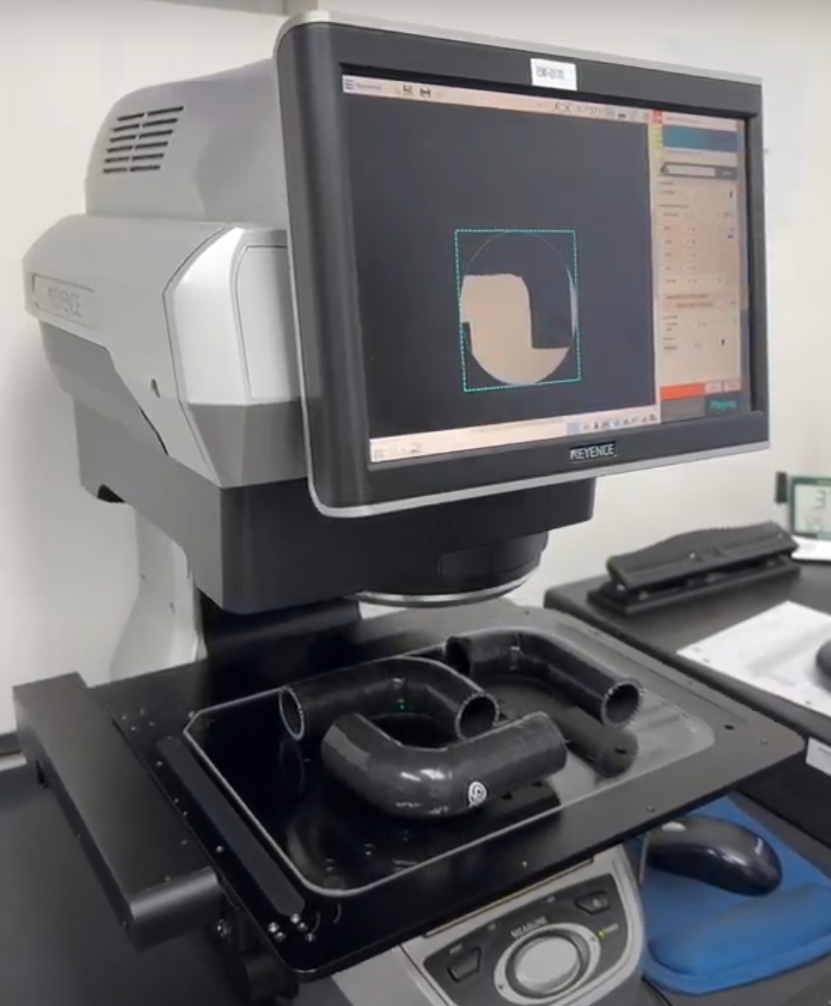

Keyence Visual Inspection Machine IM8030T

We have the top of the line visual inspection system from Keyence for quickly and accurately taking measurements of small to medium sized parts. 1 or many parts are placed onto the glass table and the system analyses the parts in a matter of seconds. We are able to take 10s of measurements on 10s of parts in seconds with this special equipment. We also have the capability to take thickness/height measurements using either a low force or non contact probe. This tool is used for initial production runs, PPAP measurements, internal checkoffs to start production, measurements of small mold inserts, and AQL measurements for some production parts when we are not able to do a 100% inspection on our Doss Visual Inspection system.

Ver todos los detalles

Precise Measurements

Not only can we use this cutting edge technology to quickly and accurately take measurements of molded parts, but we also use it for measurements of mold components. We can take many measurements in a matter of seconds for critical components of molds to ensure that all dimensions are in specification before molding parts to save time, and ensure molds are made to specification the first time. We can take measurements with 0.00007" (2um) of precision with this tool.

Ver todos los detalles100% Inspection

We perform 100% inspection for parts up to 80mm in diameter using the top of the line visual inspection system from Doss. Our equipment is able to inspect up to 14 parts a second, measure the cross-section, and take photos from 7 different angles including underneath the part using a glass table to inspect the parts. We use AI and special algorithms to detect for non fills in the part, cuts, measure flash, and take critical measurements. The parts with dimensional or cosmetic issues are automatically sorted from the good parts using a compressed air sorting system in this system. All of the test data is saved in a database and statistical reports are automatically generated. We can supply CPK, other reports, and even all of the dimensional measurements for millions of parts if desired.We can be confident in 0 defects in our products because we have the best of the best equipment to do 100% inspection of high volume parts.

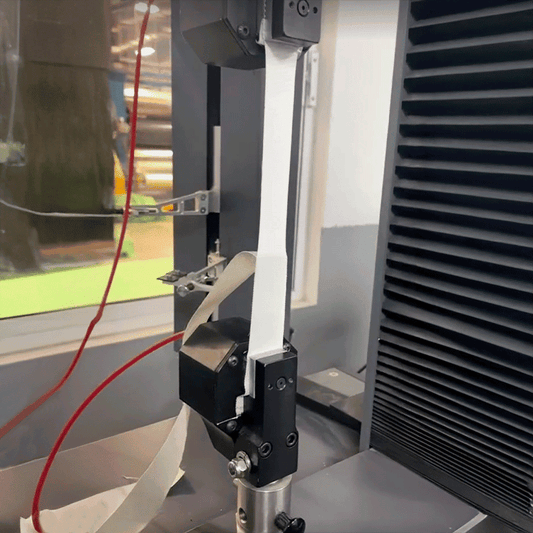

Ver todos los detallesTensile Tester

The tensile tester machine is an essential tool in evaluating the mechanical properties of our materials. By measuring tensile strength, elongation, and other key performance indicators, we can guarantee that our products can withstand the demands of their intended applications.

Ver todos los detalles3D Scanning

The tensile tester machine is an essential tool in evaluating the mechanical properties of our materials. By measuring tensile strength, elongation, and other key performance indicators, we can guarantee that our products can withstand the demands of their intended applications.

Ver todos los detallesOther Common Tests

-

Ultraviolet (UV) Resistance of Rubber Compounds (SAE J2527, ASTM D1148, ASTM D4329)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Staining (ASTM D925)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Spectrophotometer (Color Measurement)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Plasticity Testing (ASTM D926)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Ozone Resistance Testing (ASTM D1149)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Low Temperature Resistance (ASTM D2137)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Fluid Immersion (ASTM D471)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Compression-Deflection (ASTM D575)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Compression Set (ASTM D395)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Cleanliness of Rubber Product (ASTM 5774, SAE J1726)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Abrasion Testing

Precio habitual $0.00Precio habitualPrecio unitario / por -

Adhesion (ASTM D429, ISO 36)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Heat Aging (ASTM D573)

Precio habitual $0.00Precio habitualPrecio unitario / por