Fluorosilicone (FVMQ)

Fluorosilicone (FVMQ)

Fluorosilicone (FVMQ): Fuel-Resistant Silicone Elastomer

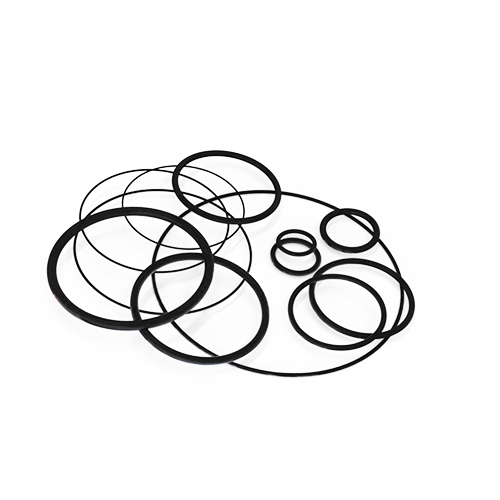

Fluorosilicone (FVMQ) is a high-performance elastomer that blends silicone’s extreme temperature flexibility with the fuel and oil resistance of fluoroelastomers. It is widely used in aerospace, automotive, military, aviation, and industrial applications requiring durable sealing performance in harsh environments and exposure to petroleum-based fluids.

Key Properties

- Wide Temperature Range: Operates from -75°F to 350°F (-60°C to 177°C), offering the broadest range among fuel-resistant elastomers.

- Fuel & Oil Resistance: Compatible with gasoline, diesel, aviation fuels (Jet A, JP-4, JP-5), and mineral oils.

- Low-Temperature Flexibility: Remains flexible at cryogenic temperatures.

- Compression Set Resistance: Maintains shape and sealing force under extreme temperature cycling.

- Chemical Resistance: Withstands aliphatic hydrocarbons, hydraulic fluids, and aviation chemicals.

- Environmental Resistance: Excellent UV, ozone, and weather aging performance; self-extinguishing flame behavior.

Common Applications

- Aerospace: Fuel system O-rings, gaskets, seals for tanks and lines.

- Automotive: Fuel injector seals, turbocharger gaskets, fuel-system components.

- Military & Aviation: Cold-weather seals, fuel-handling equipment, aircraft fuel systems.

- Industrial & Marine: Fuel-resistant hoses, low-temperature gaskets, extreme-environment seals.

Advantages

- Combines fuel resistance with extreme low-temperature flexibility.

- Better cold-temperature performance than NBR and FKM.

- Excellent durability under temperature cycling.

- Strong UV, ozone, and weather resistance.

- Self-extinguishing with low smoke output.

Limitations

- Higher cost than NBR and comparable or higher than FKM.

- Lower tensile and abrasion strength compared to NBR, neoprene, and some other elastomers.

- Less resistant to aromatic hydrocarbons and polar solvents.

- More complex compounding and processing requirements.

Material Comparisons

- vs. Silicone: Fluorosilicone adds fuel/oil resistance; standard silicone fails in fuel exposure.

- vs. NBR: Better low-temperature flexibility and wider operating range; NBR is stronger and cheaper.

- vs. FKM: FKM offers superior chemical and high-heat resistance; fluorosilicone excels in extreme cold.

- vs. Neoprene: Much better fuel and temperature resistance; neoprene is stronger and more economical.

- vs. EPDM: Fluorosilicone provides fuel resistance; EPDM is better for water and outdoor sealing without fuel exposure.

Selection Guide

- Choose Fluorosilicone: When fuel/oil exposure combines with extremely low temperatures.

- Choose FKM: For maximum high-temperature and chemical resistance.

- Choose NBR: For cost-effective petroleum resistance at moderate temperatures.

- Choose Silicone: For extreme heat/cold conditions without fuel contact.

Technical Specifications

- Hardness: 50–80 Shore A

- Specific Gravity: 1.40–1.50

- Tensile Strength: 800–1,400 psi

- Elongation: 200–400%

- Temperature Range: -75°F to 350°F

- Compression Set: Typically <30% at 70°C

Why Choose Fluorosilicone from Rubber Mexico?

Rubber Mexico develops customized fluorosilicone compounds engineered for maximum fuel resistance and extreme temperature flexibility. With in-house molding, precision tooling, and formulation capabilities, the company supports material selection, compound development, prototyping, and full-scale production for aerospace, automotive, military, and other demanding applications.

Learn about our other materials

Rubber Mexico has 100s of compounds for a variety of compounds made internally. Learn more about the other types of materials that we manufacturer and our material development capabilities.

Other Materials

-

Silicone Rubber

Precio habitual $0.00Precio habitualPrecio unitario / por -

Ethylene Propylene Diene Terpolymer (EPDM)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Styrene Butadiene Rubber (SBR)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Neoprene/Chloroprene Rubber (CR)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Nitrile Butadiene Rubber (NBR)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Fluoroelastomer (FKM/Viton)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Thermoplastic Elastomers

Precio habitual $0.00Precio habitualPrecio unitario / por -

Fluorosilicone (FVMQ)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Devulcanized Rubber Compounds

Precio habitual $0.00Precio habitualPrecio unitario / por -

Natural Rubber (NR)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Acrylic Rubber (ACM)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Ethylene Acrylic Rubber (AEM)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Flexible PVC (Plasticized Polyvinyl Chloride)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Polyurethane (PU/TPU)

Precio habitual $0.00Precio habitualPrecio unitario / por