Thermoplastic Elastomers

Thermoplastic elastomers (TPEs) are a class of materials that combine the processing advantages of thermoplastics with the flexibility and elasticity of rubber. They can be melted and reprocessed like plastics but behave like elastomers at room temperature.

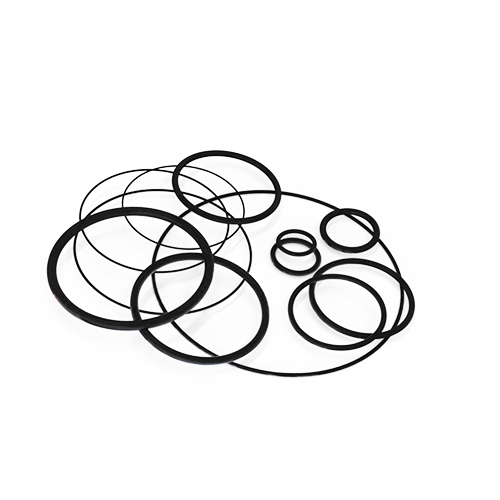

TPE Components for OEM and Heavy-Duty Equipment Manufacturers

Here’s a breakdown of the main types of thermoplastic elastomers:

-

1. Styrenic Block Copolymers (SBCs or TPS)

Examples: SBS (styrene-butadiene-styrene), SEBS (styrene-ethylene-butylene-styrene)

Features:- Soft, rubber-like feel with good elasticity.

- Processed easily via injection molding or extrusion.

- SEBS variants have better heat and UV stability than SBS.

Applications: Grips, footwear, soft-touch handles, medical tubing.

-

2. Thermoplastic Polyolefins (TPOs)

Composition: A blend of polypropylene (PP) and un-crosslinked ethylene-propylene rubber (EPR or EPDM).

Features:- Excellent weather and chemical resistance.

- Low density and good impact resistance.

- Limited elastic recovery compared to other TPEs.

Applications: Automotive bumpers, dashboards, exterior trims.

-

3. Thermoplastic Vulcanizates (TPVs)

Examples: Santoprene® (PP/EPDM-based TPV).

Features:- Made from dynamically vulcanized rubber particles in a thermoplastic matrix.

- Superior elastic recovery, oil resistance, and high-temperature stability.

- Can replace traditional vulcanized rubber in many uses.

Applications: Seals, gaskets, automotive weatherstrips.

-

4. Thermoplastic Polyurethanes (TPUs)

Composition: Block copolymers of urethane segments with hard and soft phases.

Features:- Excellent abrasion, oil, and solvent resistance.

- Wide hardness range (from flexible to rigid).

- Good transparency and toughness.

Applications: Hoses, wheels, phone cases, medical devices.

-

5. Thermoplastic Copolyester Elastomers (COPE or TPC)

- High mechanical strength and chemical resistance.

- Maintains flexibility across a wide temperature range.

- Better fatigue and creep resistance than many other TPEs.

Applications: Cable jackets, automotive boots, industrial belts.

-

6. Thermoplastic Polyamide Elastomers (PEBA)

Composition: Block copolymers of polyamide (hard segment) and polyether (soft segment).

Features:- Very low density, high elasticity, and excellent low-temperature flexibility.

- Excellent resilience and chemical resistance.

Applications: Sporting goods (shoe soles, ski boots), medical tubing.

-

7. Miscellaneous / Custom Blends

These include elastomeric PVC, specialized blends such as TPE-silicone hybrids, TPE-fluoropolymer blends, or bio-based TPEs designed for sustainability or specific performance targets.

Common Applications of TPE

Automotive Sealing & Trim Components

Industrial & OEM Rubber Components

Medical & Healthcare Components

Consumer & Electronics Applications

Why Choose Thermoplastic Elastomers (TPE) from Rubber Mexico?

At Rubber Mexico, we transform thermoplastic elastomers into high-performance components through precise molding and material expertise. Our TPE solutions deliver rubber-like flexibility, design versatility, and efficient production, ideal for demanding industrial applications that require consistency, durability, and scalability.

Need a custom Thermoplastic Elastomers solution?

Don't hesitate and reach us! Our customer service team will be happy to help you.

Learn about our other materials

Rubber Mexico has 100s of compounds for a variety of compounds made internally. Learn more about the other types of materials that we manufacturer and our material development capabilities.

-

Silicone Rubber

Precio habitual $0.00Precio habitualPrecio unitario / por -

Ethylene Propylene Diene Terpolymer (EPDM)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Styrene Butadiene Rubber (SBR)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Neoprene/Chloroprene Rubber (CR)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Nitrile Butadiene Rubber (NBR)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Fluoroelastomer (FKM/Viton)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Thermoplastic Elastomers

Precio habitual $0.00Precio habitualPrecio unitario / por -

Fluorosilicone (FVMQ)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Devulcanized Rubber Compounds

Precio habitual $0.00Precio habitualPrecio unitario / por -

Natural Rubber (NR)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Acrylic Rubber (ACM)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Ethylene Acrylic Rubber (AEM)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Flexible PVC (Plasticized Polyvinyl Chloride)

Precio habitual $0.00Precio habitualPrecio unitario / por -

Polyurethane (PU/TPU)

Precio habitual $0.00Precio habitualPrecio unitario / por